For a high-end toy aircraft design company to design an aircraft propeller model, it must take into account its later flight speed and the power transmitted by the engine. During the design process, factors such as diameter, number of blades, solidity, blade angle, and pitch must be considered. The design time is relatively long, and the company hopes to use a three-dimensional scanner to scan the three-dimensional data of the aircraft propeller and perform reverse design to speed up work efficiency.

Practical problems

1. The traditional design cycle is long and cannot meet the needs of toy aircraft design companies. Using traditional measurement methods, only part of the aircraft propeller model data can be obtained, and accurate measurement of irregular curved surfaces cannot be performed, resulting in incomplete data volume and inability to design the aircraft propeller model.

Holon solutions

In response to the problems faced by customers, Hualang 3D technical engineers put forward a solution: use the 3D scanner HL-3DS to quickly obtain the 3D data of the propeller model, and the reverse design software Geomagic Studio converts the propeller model point cloud data into triangular mesh data. Combining reverse design software to directly modify the design on the three-dimensional digital model according to customer needs, speeding up the secondary design of the propeller model.

Physical image of aircraft propeller model

Scanned image of aircraft propeller model

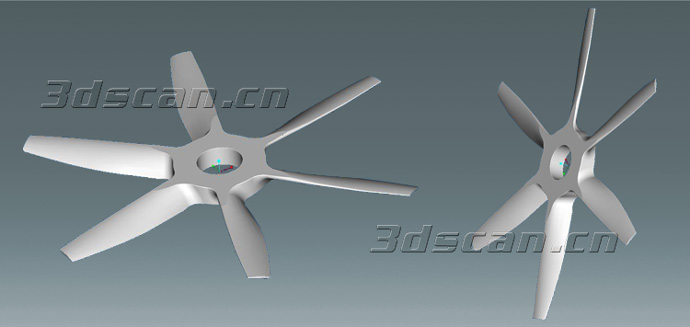

3D data of aircraft propeller model

3D data of aircraft propeller model

Scanned image of aircraft propeller model