A customer needed to obtain a high-precision three-dimensional model of an air propeller. Hualang engineers used HL-3DS to quickly and accurately obtain the three-dimensional data of the air propeller, and drew a 1:1 three-dimensional model in the reverse design software UG.

Practical problems

1. The curvature of the blades of aircraft propellers varies greatly, and traditional measurement methods cannot meet the measurement requirements.

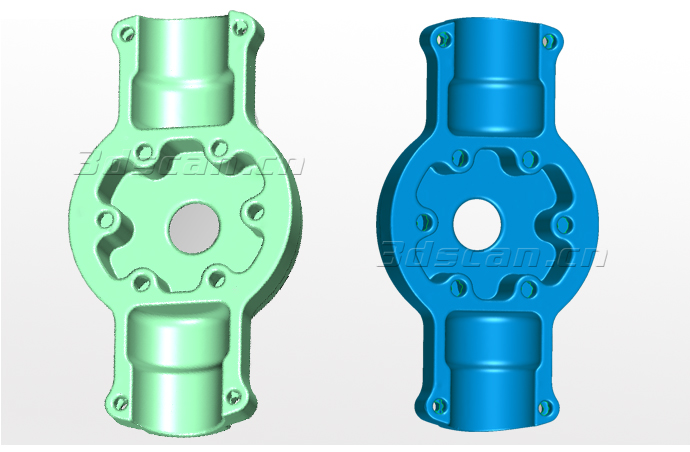

2. The hub in the middle of the aircraft propeller is a precision component that connects the engine shaft and the blades. Customers have very high requirements for data accuracy.

Holon solutions

Scanning purpose: UG drawing Scanning process

Scanning purpose: UG drawing Scanning process

Object size: total length 1830.57mm Spray imaging agent and stick mark points

↓

Use equipment: HL-3DS (two eyes) 3D scanning ↓

Measurement accuracy: single width 0.012mm Point cloud data, STL data ↓

Scan time: 30 minutes UG drawings

Blade scan scene

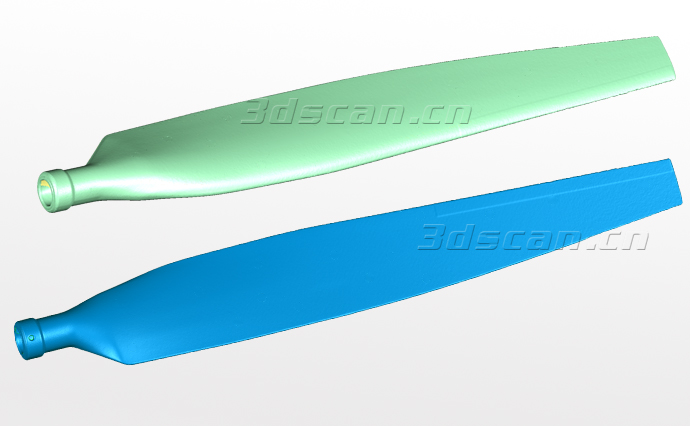

3D data of blade

An aircraft propeller is a device that converts the rotational power of the engine into propulsion or lift by rotating the blades in the air. Its quality will determine the safety of the entire aircraft. Therefore, the client hopes to use the most popular industrial measuring equipment --- 3D scanner. It is a non-contact optical measurement device with features such as fast scanning speed, high measurement accuracy, and wide range of data applications. After observing the propeller, Hualang engineers decided to use the multifunctional three-dimensional scanner HL-3DS.

Preliminary preparation:

Since the blades of the object are black and the hub is easy to reflect light, a layer of imaging agent needs to be sprayed before scanning.

Scanning three-dimensional objects requires multi-angle shooting. In order to facilitate the automatic stitching of the software, it is also necessary to paste relatively sparse marks on the propeller.

The physical map of the pulp hub

3D Data of Pulp Hub

Scanning process:

HL-3DS is a multifunctional 3D scanner independently developed by Hualang's technical team. It uses 13-step coding calibration technology to eliminate lens distortion errors. Extrapolation method multi-frequency phase shift grating technology uniform fringe projection, reducing noise. It has the characteristics of high scanning accuracy, fast scanning speed, and easy to carry.

The scanning software independently developed by Holon 3D is easy to operate and has high stability. The scanning process is simple and easy. It only takes 30 minutes to obtain a 1:1 high-precision 3D point cloud data, which can be imported into the post-processing software to be converted into STL data of triangulation structure, and it can also be imported into UG, Pro/E, etc. Mainstream software.

Holon3d engineers are using UG to draw

Aircraft propeller UG drawing