An aerospace parts manufacturing company in Guizhou uses a Hualang 3D scanner to perform 3D scanning of worn aircraft turbine blades. The blade body of the turbine blade is the carrier of energy conversion in the gas and the primary factor determining the performance of the turbine. The design requirements for the aircraft turbine blade are very high.

Practical problems

1. Aiming at the complexity of the blade edge curvature, a three-dimensional scanner is used to perform three-dimensional detection of worn aircraft engine blades, and compare and analyze with the original blade data to obtain the blade wear degree.

2. The traditional measurement method has insufficient data collection density, because the surface of the blade is irregularly curved, and the scanning accuracy of the three-dimensional scanner is very high.

Holon solutions

The structure of the turbine blade is complex and the modeling design process is cumbersome. To complete the design of the turbine blade, a detailed three-dimensional scan of the turbine blade must be done. The three-dimensional scanner scans the turbine blade model to obtain high-precision three-dimensional data and improve the design of the designer Efficiency, to ensure the accuracy of CAD design results, and shorten the product development cycle. According to the problems faced by the airline, Hualang 3D technical engineers used in the solution proposed: 3D scanner HL-3DS+ (quickly obtain high-precision 3D data of motor parts) + reverse design software (according to the high-precision obtained by the 3D scanner) Secondary design based on the 3D data) to speed up the production of aircraft turbine blades.

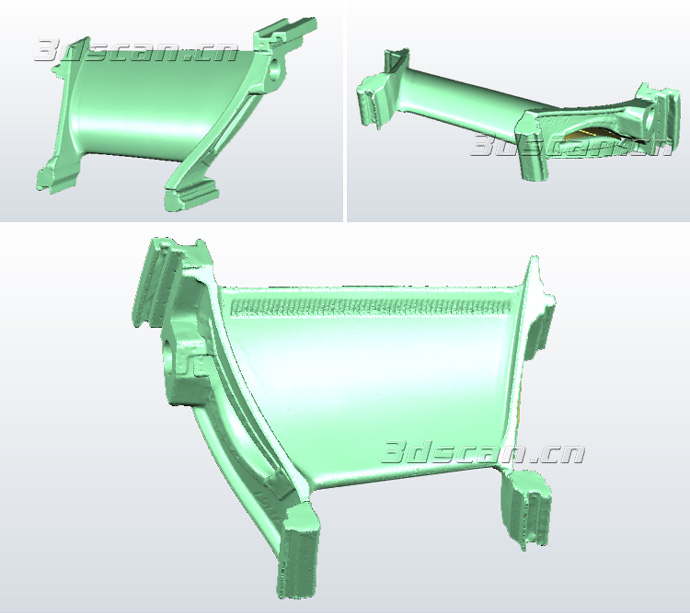

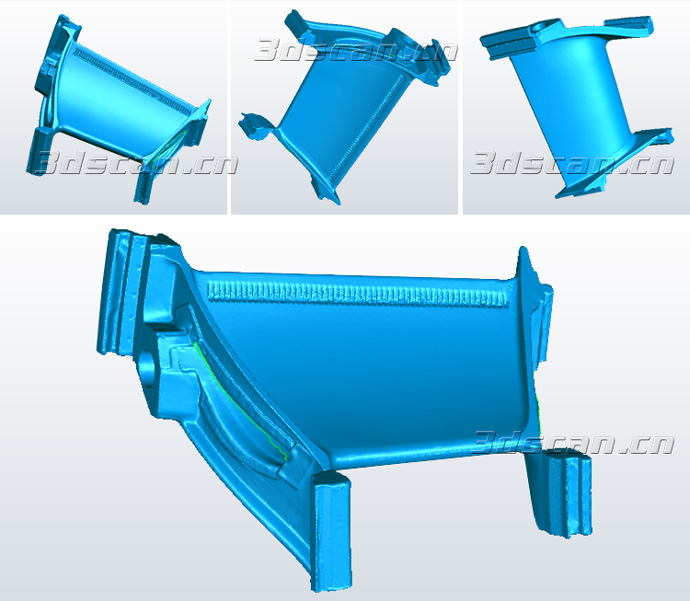

3D scanning of aircraft turbine blades

Scanning point cloud of turbine blades

Scanning STL diagram of turbine blades

Multi-function 3D scanner HL-3DS+ Product features: extrapolation method, multi-frequency phase shift grating: uniform fringe projection, point cloud data with high accuracy, no noise data, small hardware system, small footprint, no noise, easy to disassemble and easy to install , Scanning speed is extremely fast: millions of data points can be obtained within ≤3-5 seconds, extremely efficient (the system can also be customized according to customer needs), the single-frame scanning accuracy can reach 0.01mm, eliminating the multi-angle scanning of common 3D scanners The problem of splicing is extremely high, and the cumulative scanning accuracy is extremely high. A single machine can scan a workpiece of about 4m. The data has no steps, deformation, streaks and other multi-mode scanning, easy to adjust, and suitable for a variety of workpiece requirements.