An aircraft manufacturing company’s wing component product qualification rate is less than 50%, and it commissioned Hualang 3D to make a production optimization plan for their wing components, obtain high-precision three-dimensional data of wing components, and determine the precise rivet hole position. The coordinate value improves the processing efficiency and product quality of the product.

Practical problems

1. For the rivet holes on the wing parts, the traditional processing method is to use the CAD drawing to determine the hole position, and then use the electric drill to directly drill the hole. This will cause the rivet hole position to shift, leading to serious problems such as product scrap.

2. The use of traditional measurement equipment to obtain data on wing parts is limited and inefficient, and cannot detect product quality, and cannot provide accurate data support for product secondary design.

Holon solutions

The wing is one of the important parts of the aircraft, so quality control is also very important. Hualang 3D technical engineers use industrial-grade 3D scanners (HL-3DS) to quickly obtain high-precision 3D data, import the 3D data of the wing into the 3D reverse software (Geomagic) for secondary design, and successfully optimize the production plan of wing parts . Successfully solved the quality problems in the production of wing parts and provided accurate data support for the secondary design of wing parts.

Wing parts

Wing parts

1. Powder spraying and sticking

Spray developer: improve the contrast of the background color on the surface of the sample and obtain better scan data. Posting points: enable the acquired data to be positioned and spliced in the scanning software

2. Three-dimensional scanning

The scanning speed of the 3D scanner (HL-3DS) is fast, and it only takes 10 minutes to obtain the 3D data of the wing parts, and the data accuracy is as high as 0.02mm. The three-dimensional scanner (HL-3DS) uses extrapolation multi-frequency phase shift grating technology, code point calibration technology and automatic splicing technology. Matching image: On-site raster, point cloud image, import the wing parts data into the 3D reverse software (Geomagic) for processing, use the programming software to process the 3D data of the wing parts, use the program that can be accepted by the automatic drilling robot, and process Rivet holes on wing parts. The production efficiency of wing parts is significantly improved, and the product qualification rate reaches 95%, which quickly solves the problems of the wing production quality and secondary design of the aircraft manufacturing company.

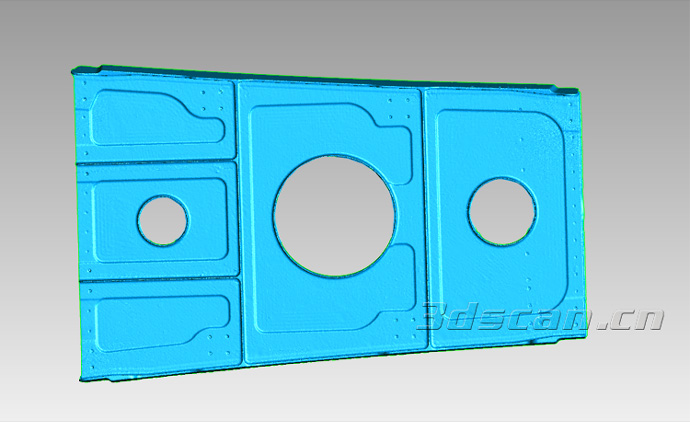

Point cloud data of wing parts

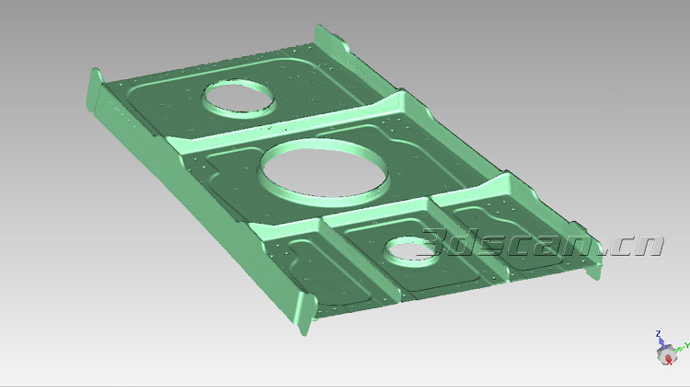

STL data of wing parts

Aircraft wing processing site