Aircraft is the embodiment of high-end manufacturing technology. Whether it is for component manufacturing, product testing, or even the aircraft assembly process, no errors are allowed, and the measurement and testing technology is extremely demanding. With professional, rigorous and rich technical means, Hualang 3D provides customers with comprehensive solutions of 3D digital technology.

Practical problems

1. Customers have very high accuracy requirements for the three-dimensional data of aircraft parts, and the overall error needs to be controlled below 0.02mm.

2. It is necessary to accurately locate the holes and grooves on the aircraft parts, and the amount of data obtained by traditional measurement methods for aircraft parts is insufficient, and it is impossible to carry out secondary design and product quality inspection.

Holon solutions

Aircraft spare parts

Aiming at the characteristics of aircraft parts, Hualang 3D engineers proposed to use in the solution: three-dimensional scanner HL-3DM (quickly obtain high-precision three-dimensional data of aircraft parts) + reverse design software Geomagic Studio (convert point cloud data of aircraft parts) Is the triangular mesh data), and carry out the secondary design of aircraft parts.

1. Preliminary preparations:

Spray the developer and paste the marking points.

2. Three-dimensional scanning:

Changing different angles of aircraft parts enables the 3D scanner (HL-3DM) to obtain 3D data of aircraft parts in all directions. It only takes 10 minutes to obtain 3D data of aircraft parts, with an accuracy of 0.01mm. The acquired point cloud data of aircraft parts is dense, and the details and features are reducible. Import the three-dimensional data of aircraft parts into the reverse design software for secondary design of aircraft parts.

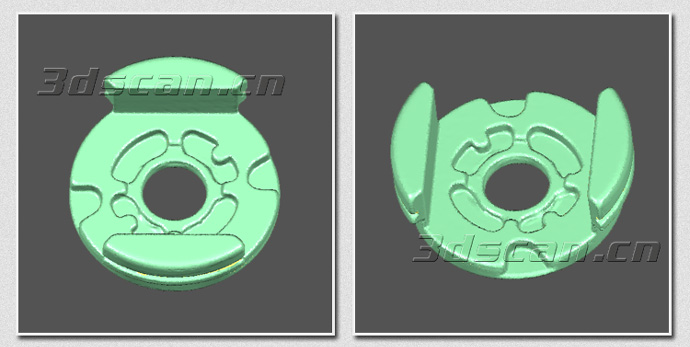

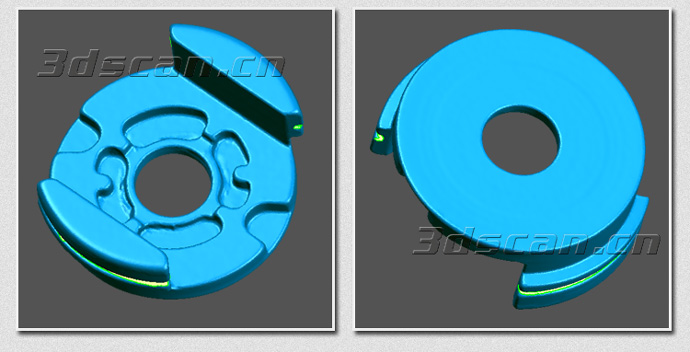

Point cloud data of aircraft parts

Point cloud data of aircraft parts