The kayak model is four meters long, and the scanning difficulty is relatively high. Hualang 3D technical engineers analyze the scans and use the 3D scanner HL-3DW developed by independent technology. It takes only 40 minutes to obtain the 3D data of the kayak model with an accuracy of 0.1mm.

Practical problem

1. The traditional measurement method has insufficient data collection density (insufficient amount of data) and cannot measure the curved surface and arc on the kayak model, cannot perform normal inspection, and cannot reverse mapping in the later stage.

2. The kayak model is 4.0m long. Generally, the scanning area of the 3D scanner is small. When scanning large objects, the accumulated scanning area is too much, and there are problems such as unable to find the mark points and not good stitching. Problems such as large workload and low work efficiency occur, and the accuracy of the acquired data does not meet customer needs.

Holon solutions

The design of the three-dimensional model to reconstruct the kayak model is costly and takes a long time, which is not conducive to product research and development. The three-dimensional scanner scans the kayak model to obtain high-precision three-dimensional data, which improves the design efficiency of reverse designers, ensures the accuracy of CAD design results, and shortens the product development cycle

Kayaking model scan scene

Aiming at the characteristics of the large area of the kayak model and more curved surfaces. Hualang 3D technical engineers proposed to use in the solution: large object 3D scanner HL-3DW (quickly obtain high-precision 3D data of the kayak model) + reverse design software Geomagic Studio (convert the kayak model point cloud data into a triangle Mesh surface data) + Pro/E, UG and other mainstream design software for post-processing to speed up the secondary design of the kayak model.

The kayak model is four meters long, and the scanning is relatively difficult. This is an area that many domestic companies are temporarily out of reach. This project was contracted by a well-known Canadian handheld three-dimensional scanner company before the company was handed over to Hualang 3D. However, the results were not satisfactory and took nearly six hours. The handheld three-dimensional scanner company said it was accurate. It can reach 0.5mm, but the scan results differ by nearly 4cm, which leads to scrapped molds and serious losses. Hualang 3D technical engineers analyze the scanned parts and use the large object 3D scanner HL-3DW developed by independent technology to obtain the complete 3D data of the kayak model in only 40 minutes, with an accuracy of 0.1mm.

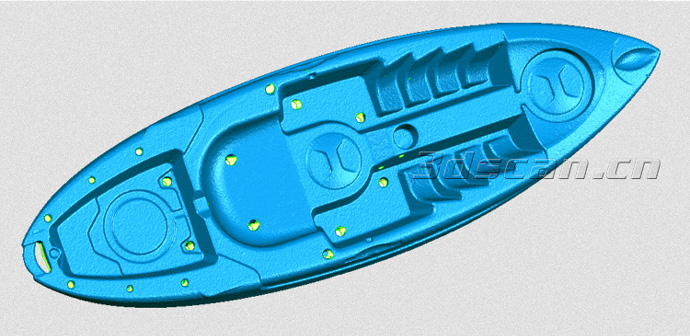

Kayak model front STL data

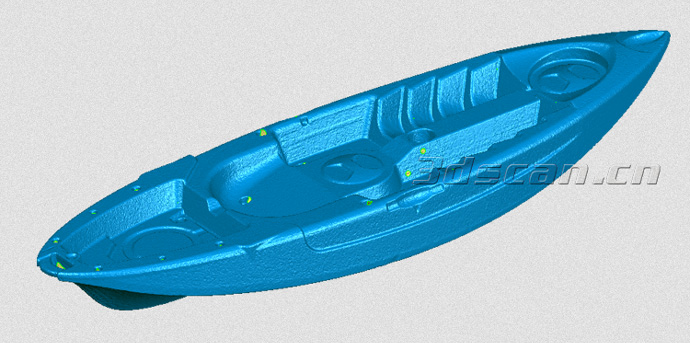

Kayak model side STL data