Helicopter is an embodiment of high-end manufacturing technology, whether it is manufactured by the assembly, or product detection, or even aircraft assembly process, no errors are not allowed, and the technical requirements for measurement detection techniques are extremely high. Hualiang three-dimensional uses a professional, rigorous, rich technical means to provide 3D digital technology integrated solutions for domestic well-known aircraft manufacturing companies.

Practical problems

1. The customer's three-dimensional data on helicopter parts is required, and the overall error needs to be controlled below 0.02 mm to ensure the accuracy of the helicopter fitting.

2. Precisely position the screw holes on the helicopter fitting to ensure that subsequent assembly is carried out.

3, the traditional measurement method data acquisition density is not enough (insufficient data volume) and the surface on the helicopter fitting and the curvature cannot be measured, and the detection cannot be performed, and the late stage cannot be reverse.

Holon solutions

The quality of helicopter parts directly affects the efficiency of manufacturing helicopters, so the rational design of helicopter accessories is very important. The three-dimensional scanner can perform three-dimensional scan for complex helicopter accessories, acquiring high-precision 3D data, increasing the design efficiency of the reverse designer, ensuring the accuracy of the CAD design results, and provides the quality assurance of the molding work.

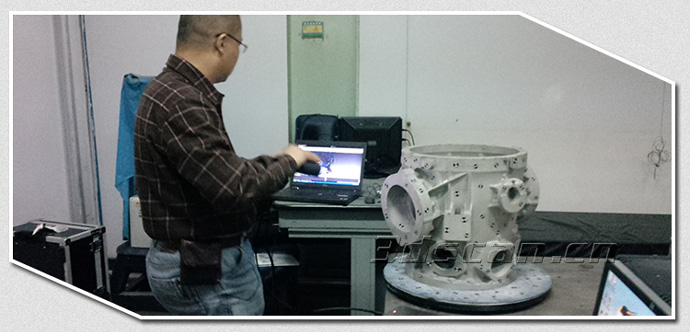

Helicopter accessories scan site

For the problems faced by customers, Huang 3D technical engineers provide professional solutions - hand-held three-dimensional scanner HL-3DH-3M (fast helicopter accessories high-precision 3D data) + reverse design software Geomagic Studio (Helicopter accessories Point cloud data conversion to triangular grid data) + PRO / E, UG and other mainstream design software for helicopter accessories, speed up the production of helicopter parts.

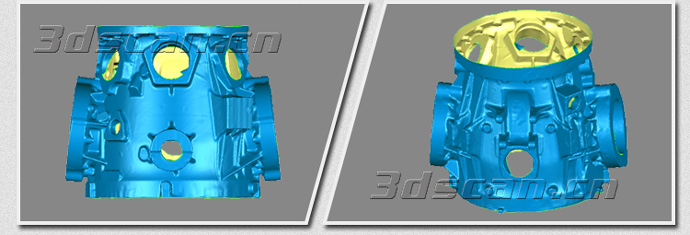

Using a handheld three-dimensional scan HL-3DH-3M instrument to obtain the precise three-dimensional data of helicopter parts, the hand-held three-dimensional scanner comes with a three-dimensional photographic measurement system, with high-precision target, and the problem of high-quality data accuracy requirements is also solved. . Import 3D models into the reverse modeling software for surface shape. After using Geomagic Studio to reverse design, it takes time to obtain deviation results in time. The detection software can be meticulous to analyze the object characteristics, such as aperture, contour, curvature, and the like, and also capture and embody the shape deviation of the profile, such as parallelism and roundness. The traditional detection software can only be compared to CAD data and scan data. The detection software automatically completes the coordinate system of the measurement data to CAD data, thereby achieving rapid alignment detection and quality control. The CAD data of helicopter accessories can be obtained by mainstream design software such as PRO / E, UG, and shorten helicopter parts production cycle. Through a series of advanced hardware and software, the company successfully established reverse design and measurement detection for helicopter machine, which laid a solid foundation for the research and breakthrough of high-end technology in this field.

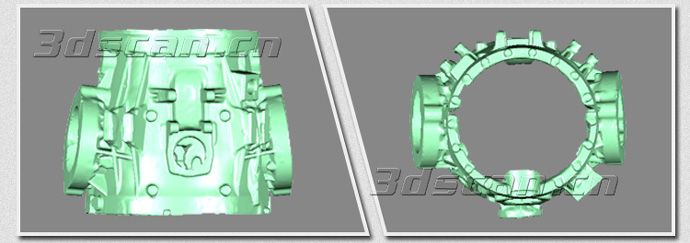

Helicopter accessories point cloud data

Helicopter accessories point cloud data