Aviation helmets can not only greatly reduce the working pressure of the pilots, but also allow the pilots to fight with peace of mind. The helmets contain sights, communication equipment, and a display of aircraft flight data. In the unlikely event of an aircraft accident, the helmet can also protect the pilot when the pilot jumps! Use a 3D scanner to obtain 3D data of aviation helmets, improve the structure of the helmet, and enhance the performance of the helmet.

Practical problems

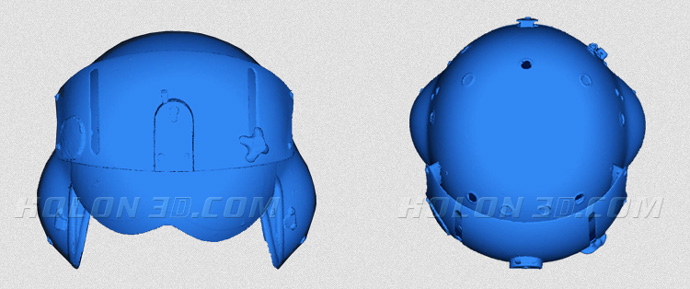

1. The inner layer of the aviation helmet is too hierarchical, and there are many curved surfaces and grooves, which increase the difficulty of scanning.

2. The traditional measurement method has insufficient data collection density (insufficient amount of data) and cannot measure the curved surface and arc of the aviation helmet, and cannot be tested normally, and cannot be reversed for drawing in the later stage.

Holon solutions

1. Case requirements:

Customers need to develop new aviation helmets and need to obtain 3D data of existing helmets for reference

Aviation helmet

2. Accuracy required by customers:0.02MM

3. Actual scanning accuracy:<0.02MM

Aviation helmets have the characteristics of complex shapes, small batches, large differences in part specifications, and high reliability requirements. Therefore, product shaping is a complex and precise process that often requires multiple designs, tests and improvements, which is expensive and time-consuming. Hualang 3D engineers proposed to use in the solution: 3D scanner HL-3DSV (quickly obtain high-precision 3D data of aviation helmet) + reverse design software Geomagic Studio (convert aviation helmet point cloud data into triangular mesh surface data) + Pro /E, UG and other mainstream design software for post-processing to speed up the secondary design of aviation helmets. It can quickly manufacture the samples required for aviation helmets, and simulate the final shape of the aviation helmets (functional shape, curved surface shape, etc.), which can be used for product testing, assembly testing, evaluation, function explanation and other functions, which can be shortened compared with traditional processes. About 1/4 of the production time. Compared with traditional processes, Hualang's three-dimensional molding process is not limited by shape and structure, and can quickly complete arbitrarily complex shapes without any molds. The result of the production is not only high precision, fine detail production, high surface quality in line with the technical requirements of aerospace, but also lightweight upgrade to a certain extent.

3D data of aviation helmet