Wind is a new energy with great potential. At present, the energy obtained by burning coal in the world every year is only one third of the energy provided by wind in a year. Therefore, both at home and abroad attach great importance to the use of wind power to develop new energy. Blade is the most basic and key component in wind turbine. Its good design, reliable quality and superior performance are the decisive factors to ensure the normal and stable operation of the unit.

Practical problems

1. In the three-dimensional measurement of blade, due to the large object to be measured, the accumulated error will be too large when using the photographing three-dimensional scanner. How to eliminate the influence of the error is the biggest problem.

2. There are many curved surfaces in the blade shape, and it is difficult for light to shine in some places, which increases the difficulty of scanning.

3. The traditional measurement method has limited data and can not accurately express the three-dimensional data of wind turbine blade surface, and can not carry out the secondary design and quality inspection in the later stage.

Holon solutions

Blade is the most basic and key component in wind turbine. Its good design, reliable quality and superior performance are the decisive factors to ensure the normal and stable operation of the unit. Customers use 3D Scanner + 3D Photogrammetry System hl-3dp to obtain 3D data of wind turbine blades, improve blade structure and enhance blade performance.

Wind turbine blade

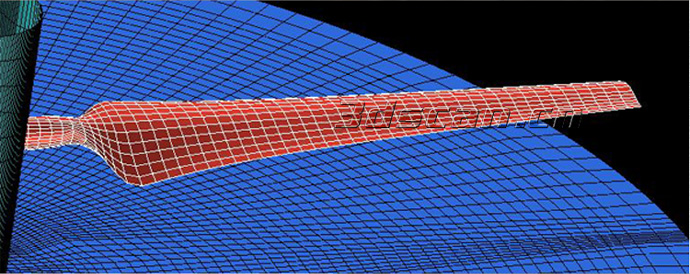

In view of the large area and many curved surfaces of wind turbine blades, Hualang 3D engineer proposed the following solutions: 3D Photogrammetry System hl-3dp (calculating 3D coordinate values of key information points on the surface of wind turbine blade) + 3D scanner hl-3dwv + (quickly obtaining high-precision 3D data of wind turbine blade) + reverse design software Geomagic studio (converting point cloud data of wind turbine blade into triangular mesh data) + pro /E. UG and other mainstream design software for post-processing, secondary design of wind turbine blades.

a. Holon3D engineers use the 3D photogrammetry system HL-3DP to take pictures of the tested blades from different angles, and then import the captured pictures into the photogrammetry software, and the software will automatically calculate the whole of the tested blades according to the principle of triangulation. Frame point. Then import the software to calculate the frame points of the wind turbine blades into the three-dimensional scanning software HLOLON3DS, and use the frame point data as the positioning skeleton to stitch the scanned data, which can effectively eliminate the cumulative error and achieve the best three-dimensional measurement accuracy.

b. The three-dimensional scanner HL-3DWV+ performs a comprehensive three-dimensional measurement of the long wind turbine blades to obtain the three-dimensional measurement data of the wind turbine blades.

c. Use reverse design software to analyze the deviation of the digital model size of the high-quality surface model, and then make design adjustments based on the analysis results.

d. The CAD data finally output by the reverse modeling software can be used for CNC machine tool processing, rapid prototyping, appearance quality inspection and other applications.

3D data of wind turbine blade