A centrifugal fan relies on input mechanical energy to accelerate gas through a high-speed rotating impeller. A centrifugal fan is composed of a casing, main shaft, impeller, bearing transmission mechanism, and motor. The speed of the fan can not only cancel throttling losses, but also ensure that the fan always operates in an efficient area, thus greatly saving electricity. This reflects the new trend of current industrial production.

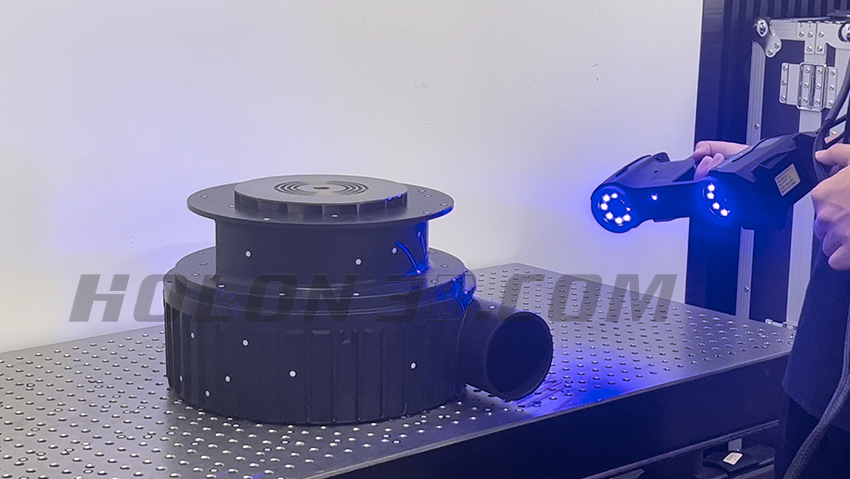

Product physical image

Practical problems

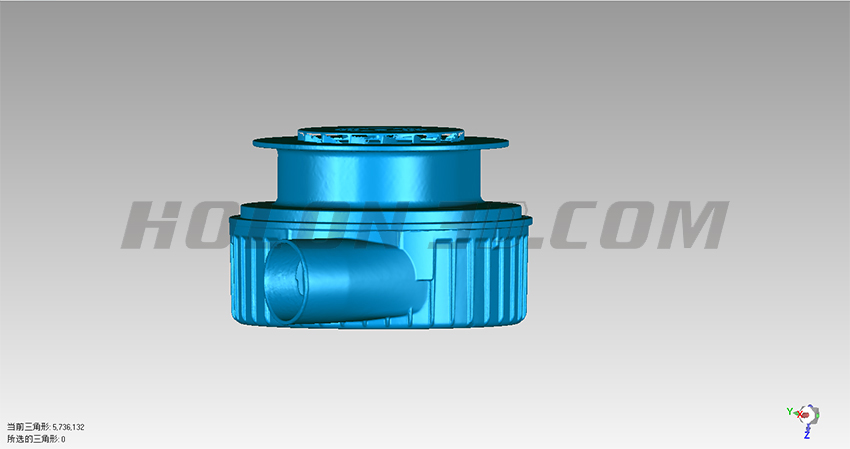

The customer hopes to obtain 3D data of the casing and impeller, establish a comprehensive 3D mathematical model, and use it for product construction design, modification design, and subsequent quality inspection.

1. The surface of the casing appears dark black and uneven, with many curved surfaces and details that are difficult to scan. Using traditional detection methods, many dimensions and shape features cannot be effectively measured, leading to secondary errors

2. Customers need to scan 3D data for reverse modeling, which requires fast scanning speed, complete data, and high accuracy, which poses great challenges.

Scan on-site images

solutions

In view of the problems faced by customers, Hualang 3D technical engineers used the handheld 3D scanner HOLON B71 to quickly and accurately obtain the 3D data of the casing and impeller, and it is convenient and fast to scan without spraying developer, with fast scanning speed and comprehensive data. Successfully solved the problems faced by the customer.

Product STL Data Chart1-1

Product STL Data Chart1-2