The turbine volute is one of the commonly used equipment in hydropower plants at present. The huge energy generated by the drop of high water level makes the volute undergo regular maintenance. There are many disadvantages in the previous maintenance. In order to further save the maintenance time and cost, the manufacturer decided to use the Hualang handheld 3D scanner for inspection:

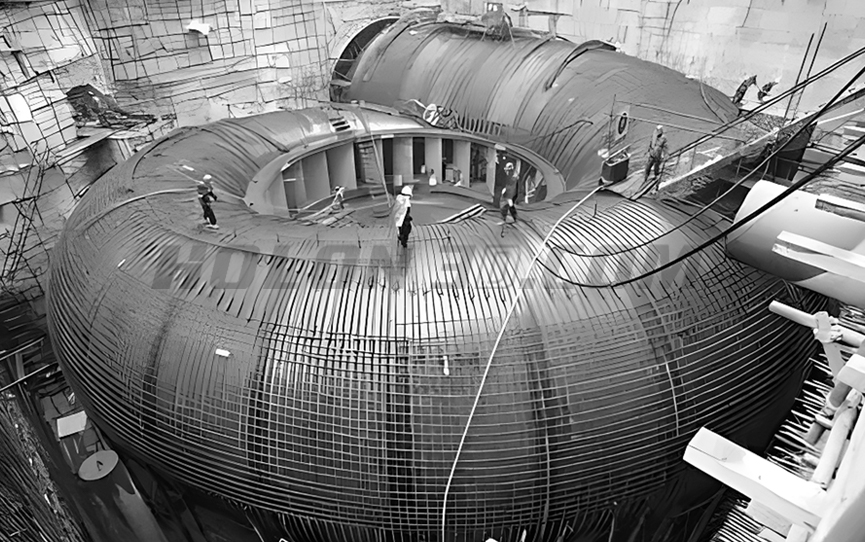

Physical drawing of turbine volute

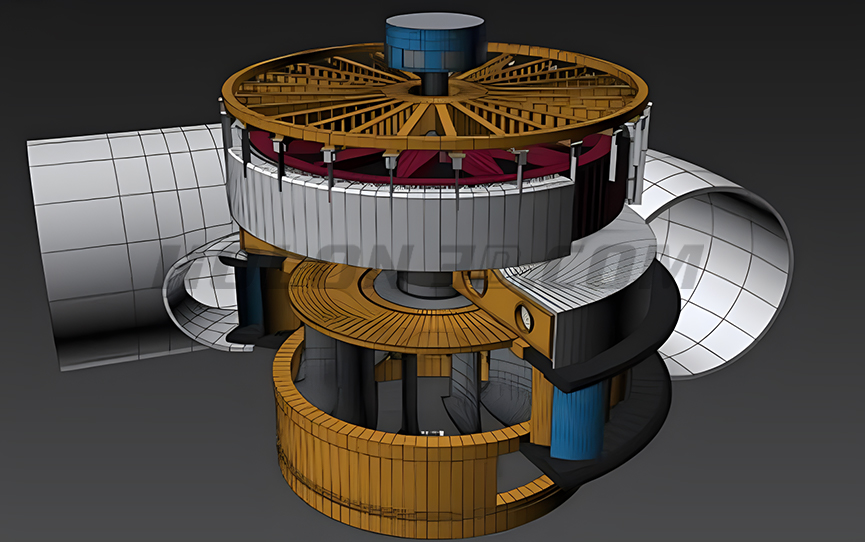

Structural drawing of turbine volute

Practical problems

The internal space of the volute is narrow, which has a great limit on the detection space

The overhaul area is large, and all scanning work needs to be completed within the time limit of the manufacturer

The surface of spiral case is rusty and muddy, which requires high data accuracy during scanning

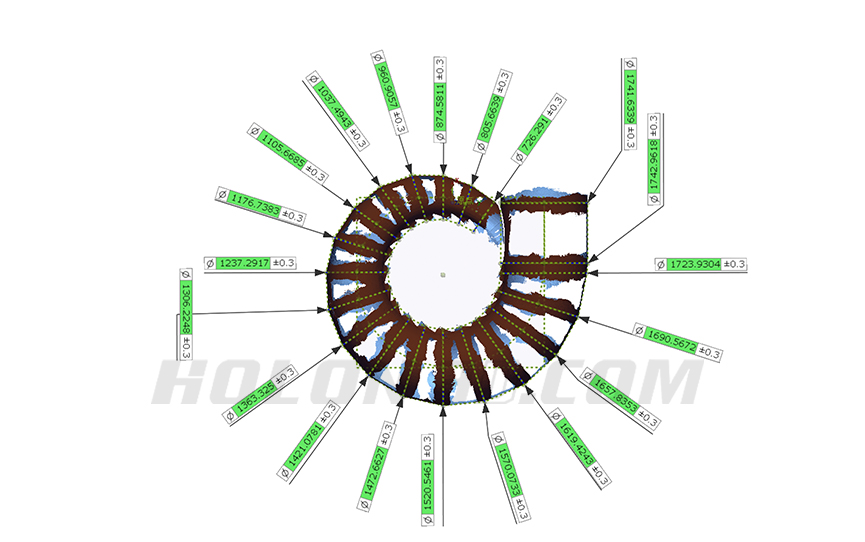

Internal sticking point drawing of turbine volute

Scanning site drawing of turbine volute

Holon solutions

Using handheld high-precision 3D scanner HOLON DB1:

High-precision scanning: excellent data splicing ability, with single data up to 0.01mm, to minimize the cumulative error of data splicing on the volute surface

Convenient scanning: After the staff put on the light and pasted the scanned surface with the mark points, the hand-held non-contact scanning can easily solve the maintenance problem of narrow spiral case space.

Large-range scanning: it has a large-range scanning mode, which maximizes the number of scanning laser lines, and has a powerful single-frame data capture ability. It has excellent performance when scanning the large surface of the spiral case (scanning range: 1400 × 1100mm)

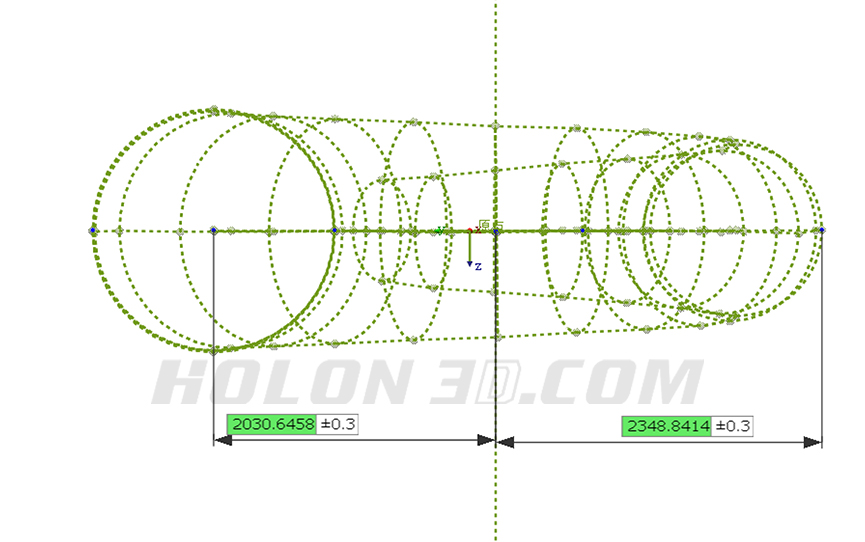

Measurement data diagram of turbine volute

Measurement data diagram of turbine volute

Through the efficient and convenient measurement method of handheld 3D scanner, the time cost of spiral case maintenance is greatly reduced, providing a solid backing for the long-term development of water conservancy projects.