A well-known auto parts manufacturing company hopes to obtain the three-dimensional data of auto lamps and establish the three-dimensional digital simulation files (CAD drawings) of auto lamps for the structural design, modification design and subsequent quality inspection of molds.

Practical problem

1. It is necessary to quickly obtain the three-dimensional digital model of automobile lamp, but the surface of automobile lamp is complex and irregular.

2. Using the traditional measurement method, only part of the data of the automobile lamp can be obtained. For the curved surface part, it can not be measured, resulting in the incomplete amount of data obtained, and the secondary design of the automobile lamp can not be carried out.

Physical object of automobile lamp

Holon solutions

The traditional lamp design is carried out simultaneously with the body design to complete the three-dimensional model of the vehicle assembly. Stamping dies are required for car bodies and injection moulds are required for lamps. After different moulds are made, they are tested, assembled and modified. This process requires the cooperation of lamp seats and lamps. That is to say, there are two uncertain factors, which increase the modification cycle and manufacturing cost.

Hualang 3D engineers use the 3D scanner hl-3dx to quickly scan the car lights, obtain high-density point cloud data, and then combine with the professional reverse design software Geomagic studio to convert the car lights point cloud data into triangular mesh surface data, which is imported into the main stream reverse software such as pro/e and UG for post-processing, so as to speed up the secondary design of the car lights and provide reliable parameters to other relevant departments, Ensure that the design results fully meet the production requirements, and speed up the production of automotive lamps. Compared with the traditional measurement and detection methods, Hualang 3D's solution can effectively reduce the detection time and greatly improve the work efficiency.

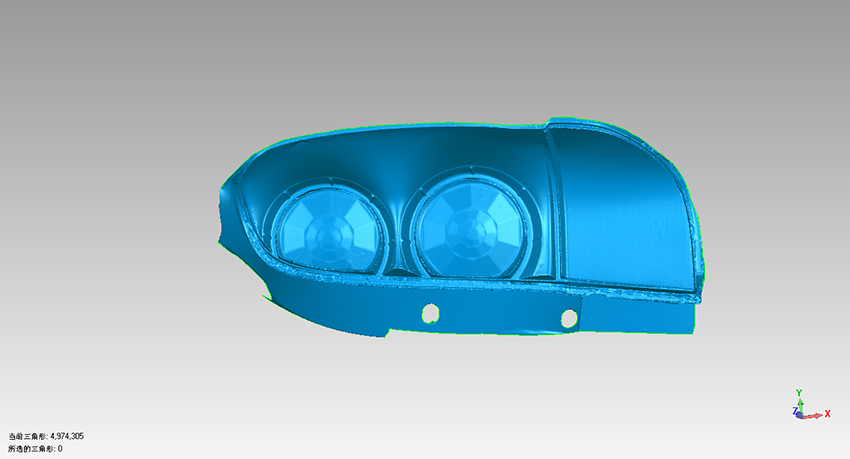

STL data diagram

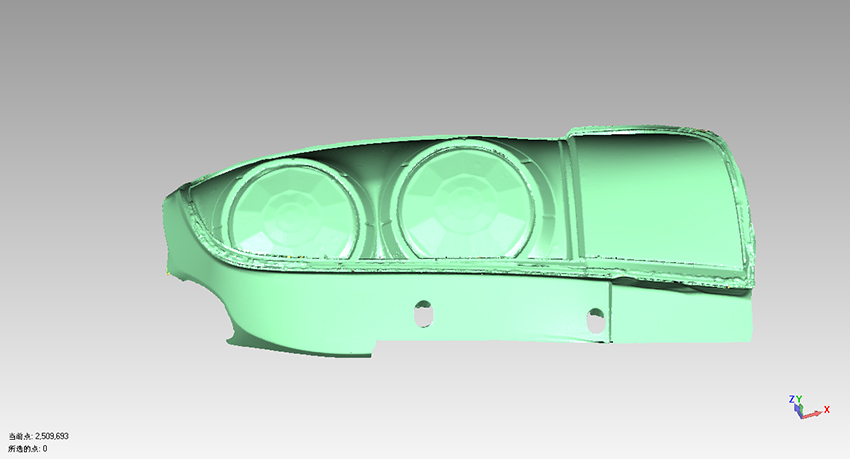

Point cloud data graph