Shock absorber is a vulnerable part in the process of automobile use. The working quality of shock absorber will directly affect the stability of automobile driving and the service life of other parts. Therefore, it is necessary to detect and repair the shock absorber to keep it in good working condition. The customer wants to use the scanner to scan the shock absorber to obtain test data for comparison and adjustment and improvement.

Practical problem

The overall outline of automobile shock absorber is complex, there are many components, many irregular details on the surface, and different sizes. The surface reflection needs powder spraying.

When using the traditional scanner, the scanning time is long and time-consuming for complex workpiece. Moreover, the micro details can not be completely scanned and captured, resulting in low data accuracy, poor scanning effect, and unable to achieve the desired results.

Field photo of automobile shock absorber

Holon solutions

Shock absorber has a great impact on the service life of automobile driving and other parts. It is conceivable that quality assurance is very important. Engineers use the holon760 handheld 3D scanner with high speed, high precision and strong stability. The device is light and portable, which is convenient for customers to carry and use. The light source uses 7 groups of cross laser lines plus an additional beam of laser lines, totaling 15 laser lines, so that the scanning accuracy is high, the capture speed is fast, the time is saved, and the work efficiency is improved; It can also switch the single laser scanning mode to scan dead corners, which can bring great convenience to customers and is easy to use. It can also display data in real time, scan data while scanning, and scan missing or incomplete data. It is very convenient to find and complete data in time.

The customer saw the demo and thought the equipment was very convenient and easy to use. After obtaining the high-precision data, import it into the three-dimensional detection software to generate a three-dimensional data chromatogram, which can be compared and analyzed with the original digital analog. The customer is also very satisfied with the scanned data, which meets the desired effect, and has great recognition for the equipment.

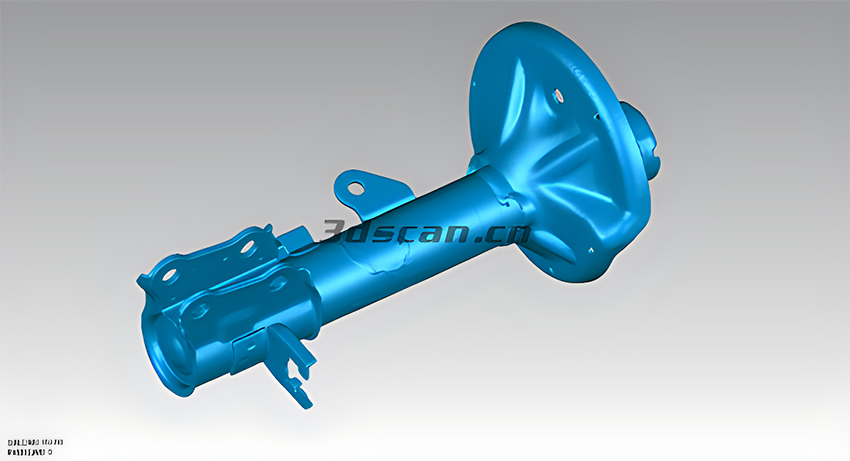

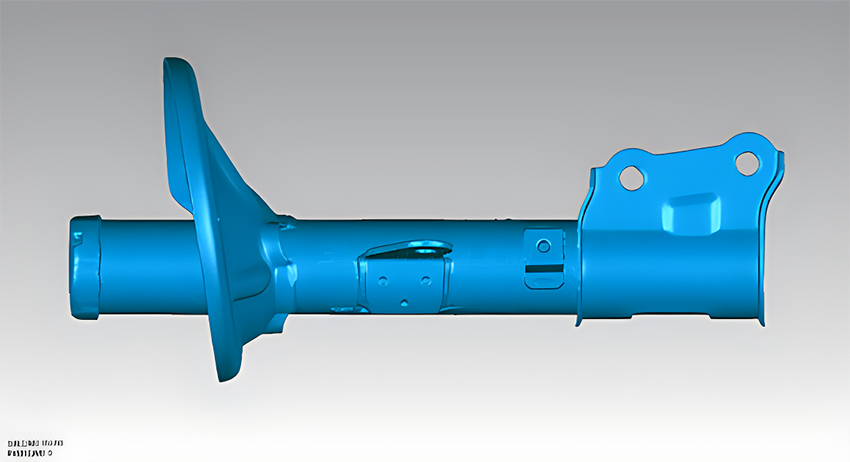

STL data diagram

STL data diagram

STL data diagram