Automotive rearview mirror plastic products account for a large proportion of automotive parts. The quality of automotive rearview mirror plastic parts is one of the important factors that affect the appearance and performance of automobiles. The quality of rearview mirror plastic injection mold plays a decisive role in the quality and cost of plastic parts.

Practical problem

1. due to the large size of the mold cavity, the cavity will be greatly deformed during production. In response to the shape change of the rear view mirror shell, the traditional measuring tools can not meet its needs.

2. since the plastic parts of the rearview mirror need to be produced in batch, in order to facilitate processing and reduce the mold cost, a three-dimensional scanner must be used for the secondary design of the product.

On site scanning of plastic parts of automobile rearview mirror

Holon solutions

For the sake of beauty, the outer surface of the automobile rearview mirror is a streamline curved surface with complex shape. Other surfaces are mostly composed of curved surfaces. There are two hollow cylindrical holes and multiple stiffeners in the middle for installation. The wall thickness of injection molded parts shall be uniform. Uneven wall thickness will lead to various defects such as internal stress, warpage and shrinkage of plastic parts. If the wall thickness is too small and the flow resistance is large during forming, it is difficult for complex products to fill the mold cavity; If the wall thickness is too large, it will not only cause excessive use of materials and increase the cost, but also increase the cooling time of plastic molding.

Scanning device:

Hualang 3D scanner hl-3ds

Applicable fields:

Mold, plastic parts, auto parts, sheet metal parts, small castings and other fields

Product features:

● extrapolation multi frequency phase shift grating: uniform fringe projection, high accuracy of point cloud data, no noise data.

● portable design: the hardware system is small in size, occupies less land, has no noise, is easy to disassemble and install, and is easy to bring to the measurement site.

● extremely fast scanning speed: ≤ 3-5 seconds, millions of data points can be obtained, which is very efficient (the system can also be customized according to customer needs).

● high accuracy: the single scanning accuracy can reach 0.01mm, which is compatible with the photogrammetry system. Photography makes the scanning speed faster and the accuracy higher, ± 0.0125mm/m.

● patented design: it can eliminate the problem that the multi angle scanning and splicing of common 3D scanners are not good. The cumulative scanning accuracy is very high. A single machine can complete the scanning of about 4m workpieces. The data is easy to adjust without multi-mode scanning such as steps, deformation and stripes. It is suitable for a variety of workpiece requirements.

STL data diagram

Point cloud data graph

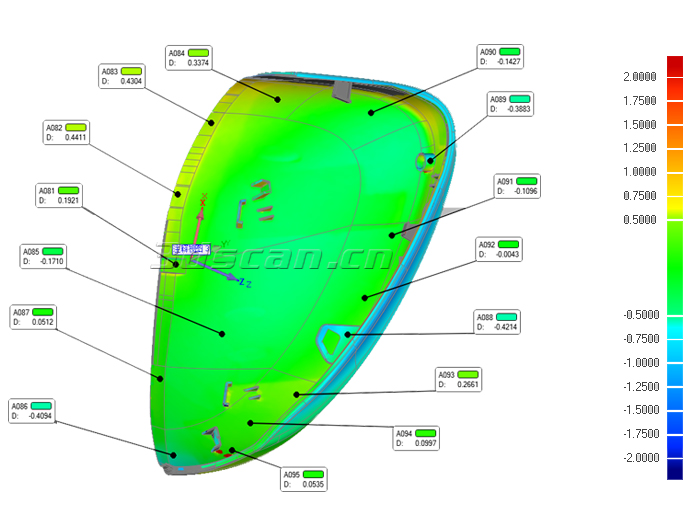

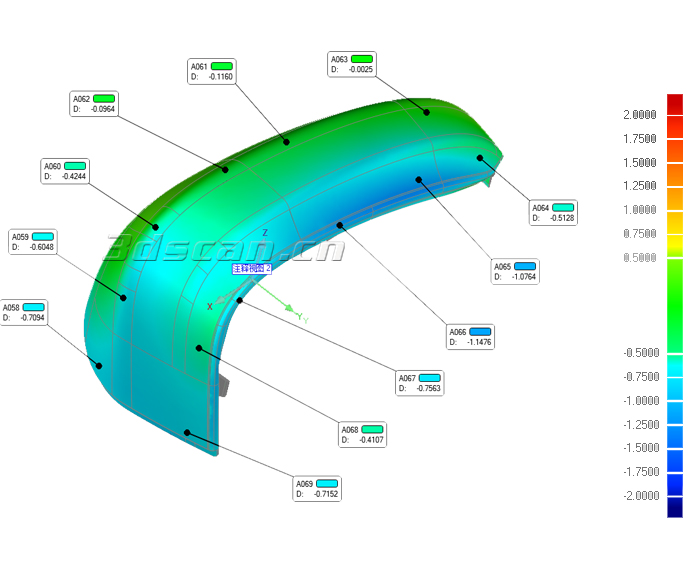

Three dimensional inspection analysis diagram

Three dimensional inspection analysis diagram