The customer is a well-known manufacturer of motorcycles. In order to meet the market demand and improve the competitiveness of the enterprise, the customer decided to abandon the traditional measurement methods and introduce new measurement means (using our company's handheld three-dimensional scanner A15 for three-dimensional detection) to modify and design the motorcycle, so as to improve the overall performance and appearance design of the motorcycle, and improve the product development speed and later product improvement.

Practical problem

Effect drawing of refitting off-road motorcycle

This case:

Hualang customers: famous motorcycle manufacturers

Scanning object: off-road motorcycle parts scanning and modification detection

Testing equipment: laser handheld 3D scanner A15

Measurement demand: detect the quality deviation of motorcycle parts after production and refitting, find out the possible problems of the product, analyze and adjust according to the detected data, and improve the unreasonable part of the product structure.

Motorcycle accessories are small in size, and the workpiece surface has an irregular surface. The traditional detection method is to use a coordinate measuring machine to obtain data in the way of dot. Due to the complex surface of the sample, it is difficult to determine the reference point of the CMM, and it is impossible to obtain complete 3D data, which takes a long time and wastes too much human and material resources.

With the A15 handheld 3D scanner, the 3D scanning data of complex curved surface workpiece can be quickly obtained, and the scanning advantages are clear at a glance.

Scanning site map of motorcycle accessories

Holon solutions

As the measured workpiece is a metal reflector (powder cannot be sprayed), it is small in size and has many curved surfaces. The customer needs to quickly scan and obtain high-precision 3D data of the motorcycle for product quality inspection. According to the customer's needs and the characteristics of the scanned object, Hualang engineers use the handheld 3D scanner holon760 to quickly scan and obtain 3D scanning data, and cooperate with the 3D detection software to conduct data analysis to detect whether the product is qualified.

On site physical drawing of motorcycle accessories

Main features of the handheld 3D scanner A15:

◆ ultra portable, equipment weight is only 0.87kg;

◆ precision up to 0.020mm, resolution up to 0.050mm;

◆ higher accuracy in combination with photogrammetry system

◆ high speed scanning: 480000 measurements / second;

◆ strong stability, fast scanning speed, simple and convenient operation;

◆ almost unlimited 3D scanning, not affected by object size, material, color, etc.

Scanning process and test results

Hualang 3D engineers first communicated with customers in detail to understand the testing requirements and sample characteristics. Then according to experience, it is recommended to use the laser handheld 3D scanner holon760 as the detection tool.

The whole scanning process only takes 5 minutes. Finally, the obtained 3D data is imported into Geomagic software for analysis, design and improvement.

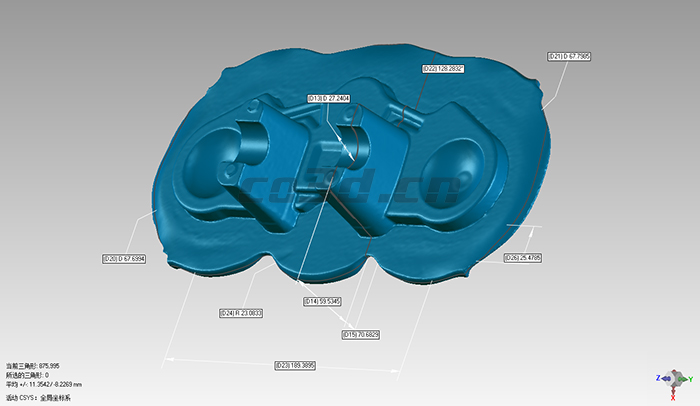

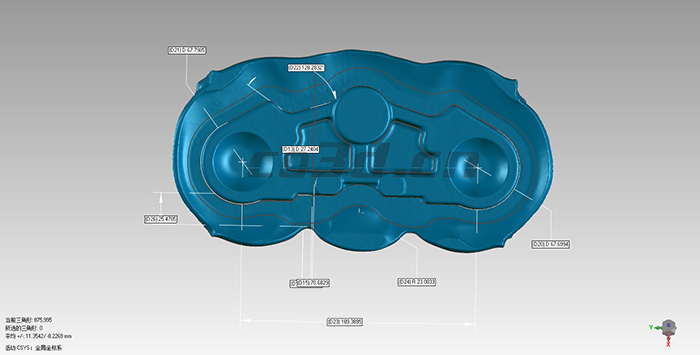

STL data diagram of motorcycle accessories

STL data diagram of motorcycle accessories

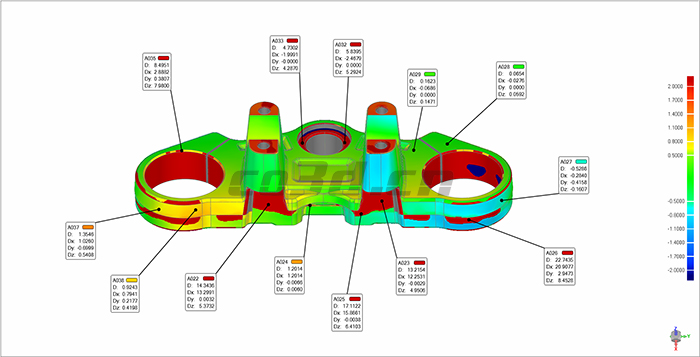

Three dimensional inspection analysis diagram

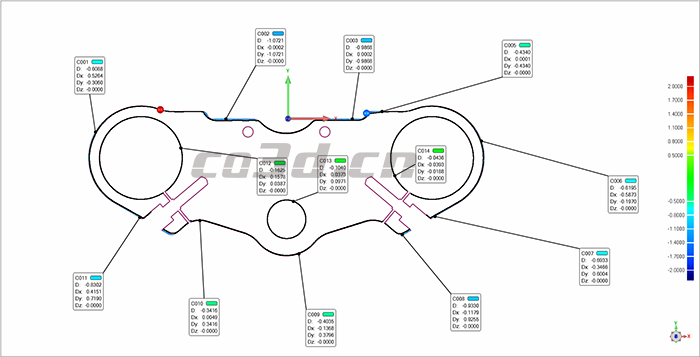

2D section