Cummins automobile engine manufacturer needs to test the engine base produced, scan and obtain high-precision three-dimensional data, and speed up the development and production of new products in combination with independent R & D and design software.

Practical problem1. As the automobile engine base involves the connection between the engine working stability and the engine body, the accuracy required by customers is very high.

2. The shape of automobile engine base is complex, there are many concave convex surfaces and holes, which bring great difficulty to the scanning work.

Scanning site of automobile engine chassis

Holon solutions

According to customer needs, Hualang 3D technical engineers put forward solutions:

1. The industrial 3D scanner hl-3ds is used to quickly and accurately obtain the 3D data of automobile engine base.

Scanning site of automobile engine chassis

Scanning site of Cummins automobile engine base

2. The scanned 3D data is imported into the reverse design software, and the point cloud data of the automobile engine base is converted into triangular mesh surface data.

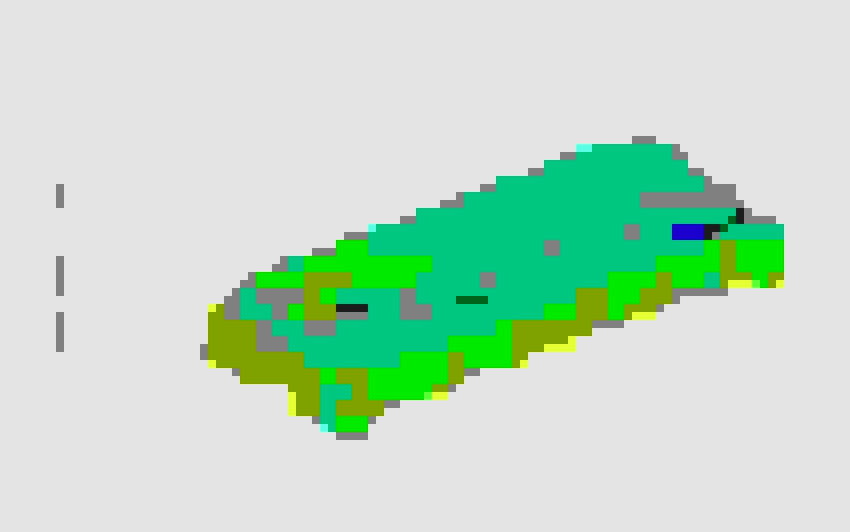

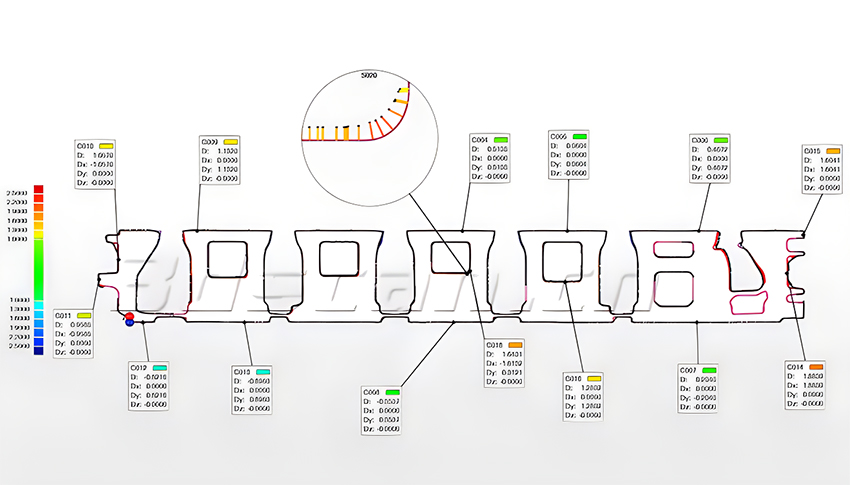

3. By importing the 3D data of the automobile engine base into the inspection software, the 3D inspection report of the automobile engine base can be quickly obtained. The report can show whether the automobile engine base has quality problems such as shrinkage and deformation, and generate an intuitive and understandable inspection graphic report to show the differences between the two. The product can be re designed to improve production efficiency.

STL data diagram of automobile engine chassis

Comparative analysis diagram of automobile engine chassis

2D sectional view of automobile engine chassis