In terms of power, sightseeing cars generally use battery cars to generate power. They are environmentally friendly, pollution-free, efficient use of resources, flexible driving, and are used in hotels, scenic spots, transportation stations and other places. Now, with the development of various industries, the demand for sightseeing cars is also increasing, and the market is gradually expanding. The customer wants to use the three-dimensional scanning technology to scan the parts of the sightseeing car to obtain the effect data, improve the production vehicles in all aspects, increase their own advantages in the market and attract more customers.

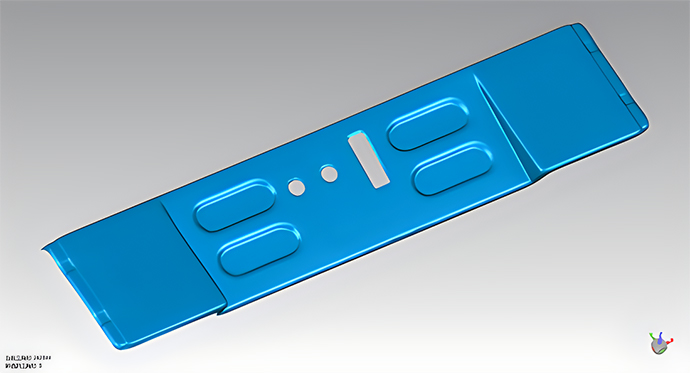

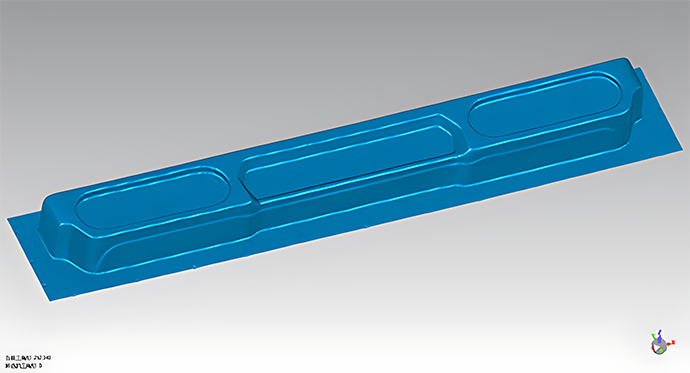

Scanning site drawing of sightseeing car parts

Practical problem In terms of power, sightseeing cars generally use battery cars to generate power. They are environmentally friendly, pollution-free, efficient use of resources, flexible driving, and are used in hotels, scenic spots, transportation stations and other places. Now, with the development of various industries, the demand for sightseeing cars is also increasing, and the market is gradually expanding. The customer wants to use the three-dimensional scanning technology to scan the parts of the sightseeing car to obtain the effect data, improve the production vehicles in all aspects, increase their own advantages in the market and attract more customers. Customers need to obtain high-precision data of scanned parts. The overall surface of sightseeing car parts is irregular and uneven, and advanced measurement methods need to be adopted for accurate measurement. If the traditional detection method is used, the workflow is complex, accurate measurement cannot be carried out, and the time is long, it will consume manpower and work efficiency is low.

Holon solutions

In terms of power, sightseeing cars generally use battery cars to generate power. They are environmentally friendly, pollution-free, efficient use of resources, flexible driving, and are used in hotels, scenic spots, transportation stations and other places. Now, with the development of various industries, the demand for sightseeing cars is also increasing, and the market is gradually expanding. The customer wants to use the three-dimensional scanning technology to scan the parts of the sightseeing car to obtain the effect data, improve the production vehicles in all aspects, increase their own advantages in the market and attract more customers. Customers need to obtain high-precision data of scanned parts. The overall surface of sightseeing car parts is irregular and uneven, and advanced measurement methods need to be adopted for accurate measurement. If the traditional detection method is used, the workflow is complex, accurate measurement cannot be carried out, and the time is long, it will consume manpower and work efficiency is low.

Scanning site drawing of sightseeing car parts

Scanning site drawing of sightseeing car parts

Scanning site drawing of sightseeing car parts