The data collection and 3D surface reconstruction of the existing car foot mats are carried out by using the Hualang handheld 3D scanner hl-3dh-3m in combination with the reverse design technology. The obtained 3D data are used for modeling and subsequent design, such as the rapid prototyping and appearance quality inspection of the car foot mats.

Practical problem

1. the pedal area of each model is different, and the design quantity is very large. However, the conventional measurement method is time-consuming and the amount of data obtained is insufficient, which is difficult to support the subsequent design and detection of the automotive floor mats.

2. it is required to scan the floor mats in the real car. The space in the car is relatively small, and the traditional measurement method cannot be operated.

Car mat scanning site

Holon solutions

Due to the development needs, the company is preparing to process and produce automotive interior molds. For the production of automobile foot pads, the company's original data acquisition method is to manually enter the vehicle interior for data acquisition. This method is inefficient and the accuracy of data acquisition is not high. In this way, there will be a large gap when the foot pads produced by the traditional process are placed at the foot, and the safety of braking behavior will be affected due to the activities of the foot pads during driving. Due to the development needs, the company is preparing to process and produce automotive interior molds. For the production of automobile foot pads, the company's original data acquisition method is to manually enter the vehicle interior for data acquisition. This method is inefficient and the accuracy of data acquisition is not high. In this way, there will be a large gap when the foot pads produced by the traditional process are placed at the foot, and the safety of braking behavior will be affected due to the activities of the foot pads during driving.

Physical drawing of car floor mat

In view of the situation faced by the company, Hualang 3D engineers use the handheld 3D scanner hl-3dh-3m to obtain the data information of car foot pads, so as to improve the efficiency and accuracy of 3D data acquisition. The hand-held 3D scanner hl-3dh-3m has the characteristics of small volume, light weight, simple operation, fast scanning and no need of external AC power supply. It can go deep into the narrow space in the car to efficiently, quickly and accurately obtain the three-dimensional data information of the car floor mat. It only takes 10 minutes, and the data accuracy reaches 0.05. The reverse design software Geomagic studio (converts the point cloud data of the car foot pad into the triangular mesh surface data) imports the obtained 3D data of the car foot pad into the mainstream reverse software such as pro/e and UG for post-processing, speeds up the secondary design of the car seat, provides reliable parameters to other relevant departments, ensures that the design results fully meet the production requirements, and speeds up the production of the car foot pad.

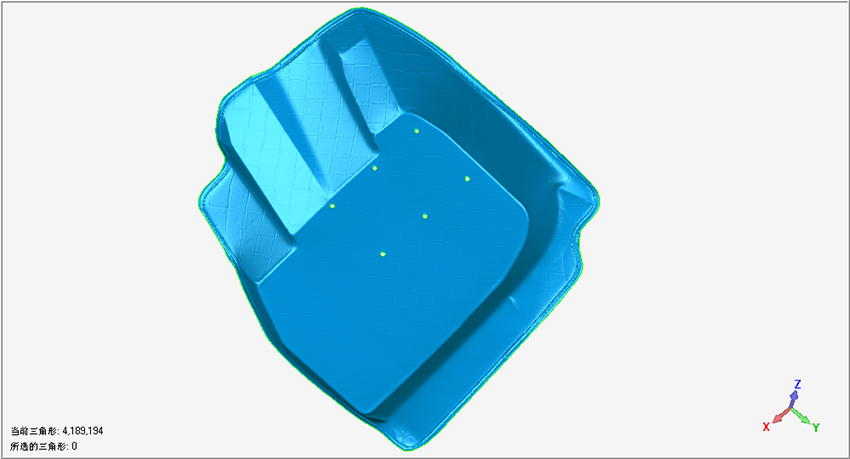

STL data diagram of car floor mat

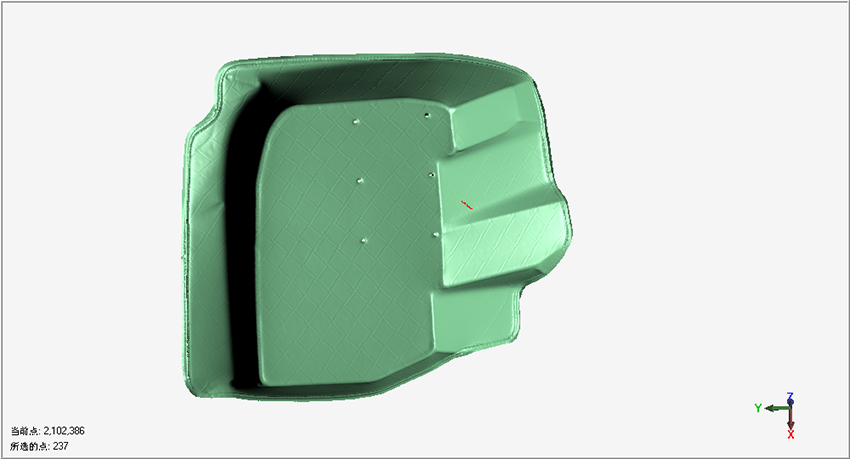

Car footrest point cloud data