The automobile instrument panel is an important part of the automobile interior trim. The data collection and 3D surface reconstruction of the existing automobile instrument panel are carried out by using the Hualang 3D scanner hl-3ds and the reverse design technology, and the secondary design is carried out according to the obtained 3D data of the automobile instrument panel.

Practical problem

1. It is very tedious and time-consuming to simply use the traditional detection methods (such as inspection tool, fixture, three coordinates, etc.). As a result, the amount of data obtained from the automobile instrument panel is incomplete, and the quality inspection and secondary design of the automobile instrument panel cannot be carried out.

2. It is necessary to quickly obtain the three-dimensional digital model of the automobile instrument panel, but the surface of the automobile instrument panel is complex, and there are many holes to match with the automobile instrument, so the accuracy is required.

Field drawing of automobile instrument panel

Holon solutions

The traditional automobile instrument panel design is carried out at the same time as the instrument design. The three-dimensional model of the whole vehicle assembly is completed, and the test mold and assembly are carried out after the production of different molds. This process requires the cooperation of the instrument panel and the instrument, that is to say, there are two uncertain factors, which increase the repair cycle and manufacturing cost. In view of the problems faced by customers, Hualang 3D engineers proposed to use in the solution: 3D scanner hl-3ds (to quickly obtain high-precision 3D data of automobile instrument panel) + reverse design software Geomagic studio (to convert automobile instrument inventory cloud data into triangular mesh surface data) + pro/e, UG and other mainstream design software for post-processing, so as to speed up the secondary design of automobile instrument panel.

1. Preliminary preparation

Spraying developer: improve the surface background color contrast of the sample to obtain better scanning data.

Paste mark points: make the acquired data be positioned and spliced in the scanning software.

2. 3D scanning

Hualang 3D engineers use the 3D scanner hl-3ds to quickly obtain high-precision 3D data of automotive instrument panels. The three-dimensional scanner (hl-3ds) adopts extrapolation multi frequency phase-shift grating technology and automatic splicing technology, with fast scanning speed. It takes only 30 minutes to obtain the three-dimensional data of the automobile instrument panel, and the data accuracy is as high as 0.03mm. The obtained 3D data of automobile instrument panel is imported into mainstream reverse software such as pro/e and UG for post-processing, so as to speed up the secondary design of automobile instrument panel, provide reliable parameters to other relevant departments, and speed up the production of automobile instrument panel.

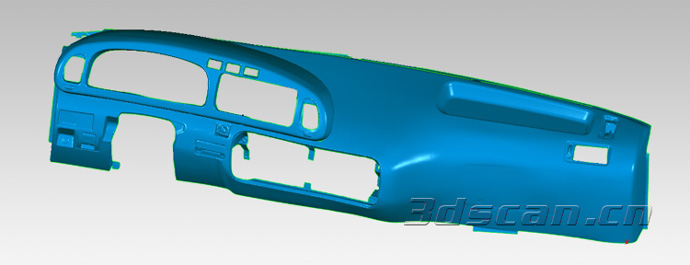

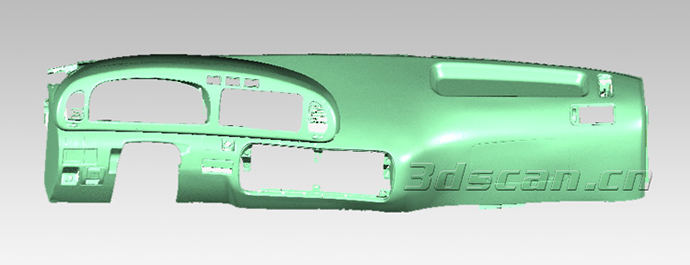

STL data diagram of automobile instrument panel

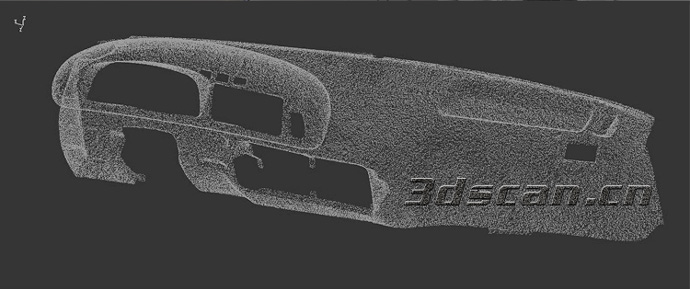

Cloud data chart of automobile instrument inventory

Cloud data chart of automobile instrument inventory