As one of the most popular transportation tools at present, electric vehicles have the characteristics of convenience, compactness, energy saving and low carbon. An electric vehicle manufacturer hopes to reverse design the electric vehicle frame and accelerate the development of new products.

Practical problem

The electric vehicle frame with the design concept of portability and environmental protection is an alloy pipe frame structure with large radian. It is difficult to obtain the three-dimensional model data of the electric vehicle frame quickly and accurately by using traditional measurement methods.

Physical drawing of electric vehicle frame

Holon solutions

According to the needs of customers, Hualang 3D engineers proposed to use in the solution: 3D scanner hl-3ds (to quickly obtain high-precision 3D data of electric vehicle frame) + reverse design software Geomagic studio (to convert engine point cloud data into triangular mesh surface data) + pro/e, UG and other mainstream design software.

1. Preliminary preparation

Spraying developer: improve the surface background color contrast of the sample to obtain better scanning data.

Paste mark points: make the acquired data be positioned and spliced in the scanning software.

Physical drawing of electric vehicle frame

2. 3D scanning

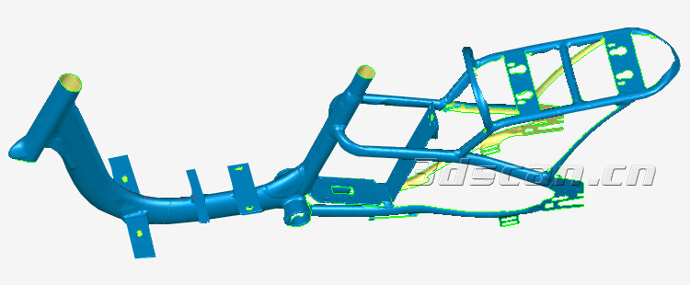

The three-dimensional scanner hl-3ds is used to scan the electric vehicle frame, then the data is imported into the three-dimensional reverse software (Geomagic) for processing, and then the processed data is imported into the mainstream design software such as pro/e and UG for reverse design of the electric vehicle frame. Accelerate the development of new products.

STL data diagram of electric vehicle frame