A well-known auto parts manufacturer needs to reverse design an auto part. The company uses the 3D scanner independently developed and produced by Hualang to obtain high-precision 3D data and accelerate the development of new products in combination with reverse engineering software.

Practical problem

1. Because this part involves the connection with multiple parts, the accuracy required by customers is very high.

2. The automobile parts have the characteristics of complex shape, large surface changes and many hole positions. The traditional measurement method is very time-consuming and the data is not accurate enough.

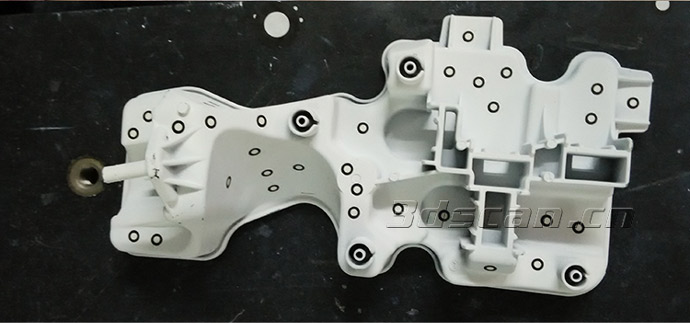

Physical drawing of auto parts

Holon solutions

In view of the characteristics of complex shape surface, large curvature change and many hole locations of auto parts, Hualang 3D technical engineers proposed a solution that uses the 3D scanner hl-3ds+ (to quickly obtain high-precision 3D data of auto engine) + reverse design software Geomagic studio (to convert engine point cloud data into triangular mesh surface data) + pro/e, UG and other mainstream design software for post-processing.

Three dimensional scanner (hl-3ds) adopts extrapolation multi frequency phase shift grating technology, coding point calibration technology and automatic splicing technology. Fast scanning speed and high precision. It takes only 10 minutes to obtain the 3D data of auto parts, and the data accuracy is as high as 0.02mm. The obtained auto parts data are imported into the three-dimensional reverse software (Geomagic) for processing, and then imported into the mainstream design software such as pro/e and UG for reverse design of auto parts, which speeds up the development of new products.

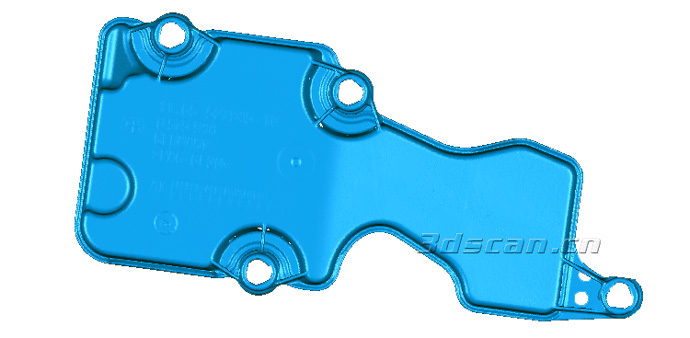

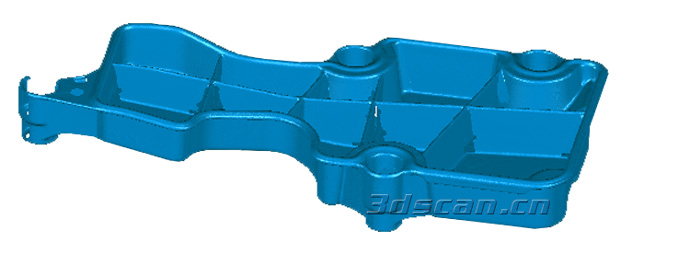

STL data diagram of auto parts

STL data diagram of auto parts