In order to improve the production efficiency of motorcycles, a large motorcycle manufacturer used Hualang 3D scanner to scan the oil sludge model of motorcycles and obtain high-precision 3D model data for relevant departments to shorten the design cycle of motorcycles.

Practical problem

1. The production of motorcycle sludge model is an important link in the design and development of motorcycle. A qualified sludge model is not only a perfect interpretation of the two-dimensional effect drawing, but also provides specific data for the later three-dimensional measurement and mold production. Therefore, the making of oil sludge model is closely related to the success of motorcycle appearance design development.

2. There are many curved surfaces of motorcycle oil sludge model, so it is very tedious and time-consuming to use traditional measurement methods (such as inspection tools, fixtures, three coordinates, etc.), and it is not easy to accurately and quickly measure the structure of motorcycle oil sludge model.

Motorcycle sludge scanning site

Holon solutions

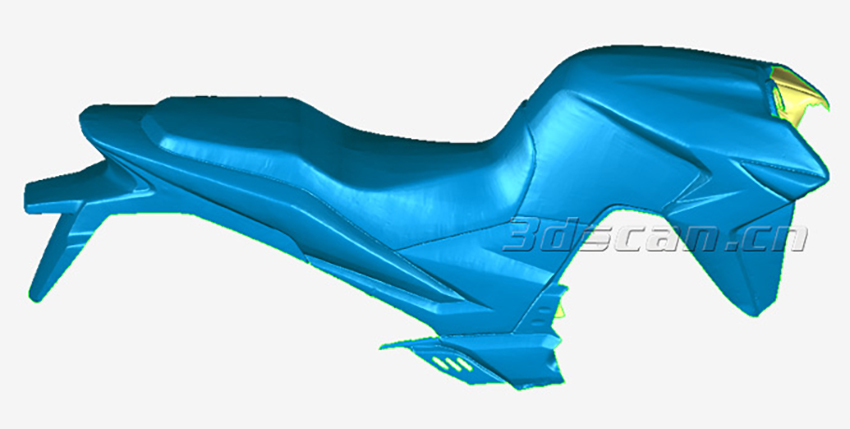

Hualang 3D engineer proposed a solution: use the 3D scanner hl-3ds+ (quickly obtain the high-precision 3D data of motorcycle sludge model) + reverse design software Geomagic studio (convert engine point cloud data into triangular mesh surface data) + pro/e, UG and other mainstream design software to solve the problems faced by customers.

The three-dimensional scanner (hl-3ds+) has a fast scanning speed. It takes less than 15 minutes to obtain the three-dimensional data of the motorcycle sludge model, and the data accuracy is as high as 0.02mm. The extrapolation multi frequency phase-shift grating technology, coding point calibration technology and fully automatic splicing technology are adopted. With the post-processing software, it can provide reliable parameters for other relevant departments, greatly shorten the motorcycle design cycle, and achieve the purpose of high-efficiency production.

STL data diagram of motorcycle sludge