The automobile transmission shaft can transfer power between the two shafts of different axes, or even between the two shafts whose relative positions are constantly changing in the working process. It is a movable or rotating round object fitting that connects or assembles various fittings. It is an important safety part of the automobile. According to the specific conditions of the company, Hualang 3D engineers used the handheld 3D scanner (hl-3dh-3m) + reverse design software Geomagic studio to carry out the secondary design of the automobile transmission shaft.

Practical problem

1. The hole position (relative position between holes) accuracy of automobile transmission shaft shall be ensured, which shall not exceed 0.05mm

2. The wall thickness and strengthening structure of the stressed part of the automobile transmission shaft are the key points of the design, and the design results directly affect the service life of the product

3. The data density collected by the traditional measurement method is not enough (the amount of data is insufficient), and the surface of the automobile transmission shaft can not be measured, and the secondary design can not be carried out in the later stage.

Scanning site of automobile transmission shaft

Holon solutions

In view of the problems faced by customers, Hualang 3D engineers proposed to use in the solution: Handheld 3D scanner hl-3dh-3m (to quickly obtain high-precision 3D data of automobile transmission shaft) + reverse design software Geomagic studio (to convert automobile transmission shaft cloud data into triangular mesh surface data) + pro/e, UG and other mainstream design software for post-processing, so as to speed up the secondary design of automobile transmission shaft.

1. Preliminary preparation

Spraying developer: improve the surface background color contrast of the sample to obtain better scanning data.

Paste mark points: make the acquired data be positioned and spliced in the scanning software.

2. 3D scanning

Hualang 3D engineers use the handheld 3D scanner hl-3dh-3m to quickly obtain high-precision 3D data of automobile transmission shaft. The three-dimensional scanner has the characteristics of small volume, light weight, simple operation, fast scanning and no need of external AC power supply. It can quickly carry out three-dimensional scanning of automobile transmission shaft and obtain high-density point cloud data. It only takes 10 minutes to get the three-dimensional data of the automobile transmission shaft, and the accuracy reaches 0.05mm. The three-dimensional data of the automobile transmission shaft are imported into the mainstream reverse software such as pro/e and UG for post-processing, so as to speed up the secondary design of the truck top cover, provide reliable parameters to other relevant departments, ensure that the design results fully meet the production requirements, and speed up the production of the automobile transmission shaft.

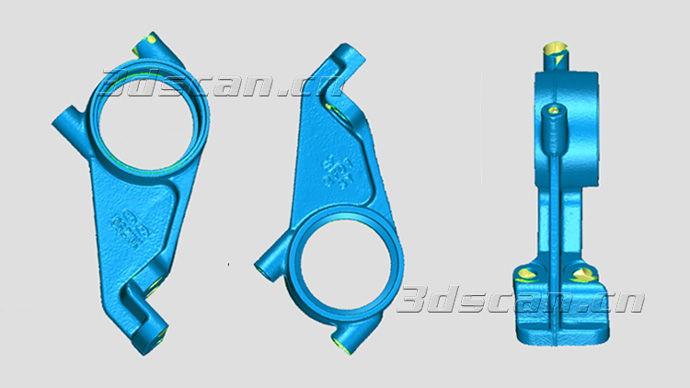

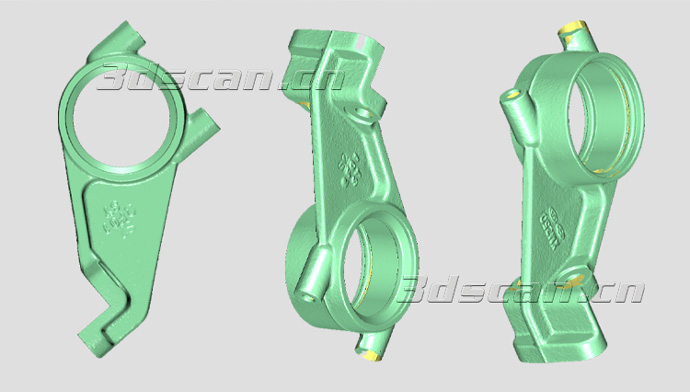

STL data diagram of automobile transmission shaft

STL data diagram of automobile transmission shaft