For the hole position of motorcycle instrument panel, there are many curved surfaces, which are also complex. The solutions proposed by Hualang 3D engineers include: 3D scanner hl-3ds (to quickly obtain high-precision 3D data of motorcycle instrument panel) + reverse design software Geomagic studio (to convert motorcycle instrument inventory cloud data into triangular mesh surface data) for secondary design of motorcycle instrument panel.

Practical problem

1. Motorcycle instrument panel has many buckle positions and hole positions, which need to be closely matched with the instruments on motorcycle. There are very high precision requirements for the three-dimensional data of motorcycle instrument panel, and the overall error needs to be controlled below 0.02mm.

2. The traditional measurement method has insufficient data collection density (insufficient data volume) and can not measure the surface and hole position of the motorcycle instrument panel, and can not provide data support for the secondary design in the later stage.

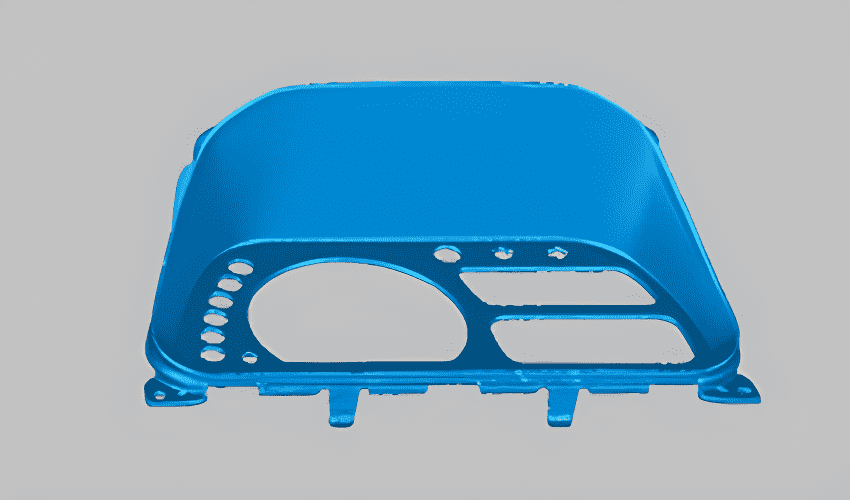

Motorcycle dashboard

Holon solutions

The customer's original motorcycle dashboard design progress can no longer meet the market demand. In view of the problems faced by customers, Hualang 3D engineers proposed to use in the solution: 3D scanner hl-3ds (to quickly obtain high-precision 3D data of motorcycle instrument panel) + reverse design software Geomagic studio (to convert motorcycle instrument inventory cloud data into triangular grid data), to carry out the secondary design of motorcycle instrument panel.

1. Preliminary preparation

Spraying developer: improve the surface background color contrast of the sample to obtain better scanning data.

Paste mark points: make the acquired data be positioned and spliced in the scanning software.

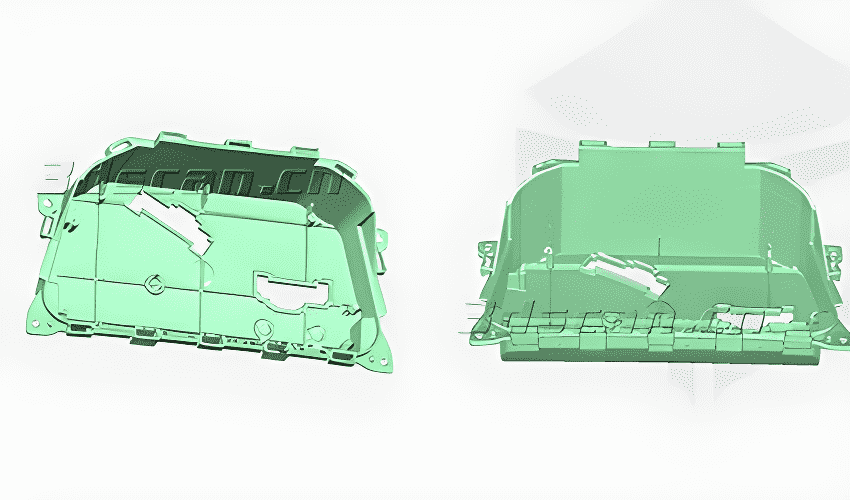

2. 3D scanning

The three-dimensional scanner (hl-3ds) has a fast scanning speed. It takes only 10 minutes to obtain the three-dimensional data of the motorcycle instrument panel, and the data accuracy is as high as 0.02mm. The three-dimensional scanner (hl-3ds) adopts extrapolation multi frequency phase shift grating technology, marker calibration technology and automatic splicing technology. Import the motorcycle dashboard data into the three-dimensional reverse software (Geomagic) for processing, quickly solve the problems of motorcycle dashboard production quality and secondary design, ensure the normal production of products, and provide a general basis for subsequent design and modification, improve the competitiveness of the company and create benefits for the company.

STL data diagram of motorcycle instrument panel

STL data diagram of motorcycle instrument panel

STL data diagram of motorcycle instrument panel