Holon engineers use 3D scanner to obtain three-dimensional data of a wind turbine nacelle cover 7000 and 3D Photogrammetry System HL-3DP, to speed up the two nacelle cover design process, shorten the product development cycle.

Three dimensional scanning field of wind turbine engine room cover

Practical problems

1, the large size of the wind turbine, the traditional method of measuring efficiency is too low.

2, the customer needs to obtain accurate data of wind turbine nacelle cover screw, the high precision measurement equipment.

Holon engineers are using HL-3DP

Holon solutions

In recent years, the rapid development of wind power in emerging markets. In the context of national policy support and energy supply constraints, China's wind power especially wind power equipment manufacturing industry is also rapidly rising, has become the world's most active wind power sites. A well-known wind power equipment manufacturers need to improve the existing part of the product. The company needs to purchase 3D scanner to obtain the 3D data of the wind power generator, which is used for the reverse design and the quality inspection of the products in the later period. The company on the performance of three-dimensional scanner is very seriously, invited a number of three-dimensional scanner supplier to the scene demonstration, which is no lack of well-known brands at home and abroad. 'Holon 3D' with superb technology and rich experience to get the company's trust, become the supplier of 3D scanner.

About 8m, about 3M high wind turbine engine room cover physical map

The size of the wind turbine nacelle is large, about 8 meters long, 3 meters wide, Holon engineers recommended use large workpiece 3D scanner alpha 7000+ 3D Photogrammetry System HL-3DP according to its size. HL-3DP is a kind of portable optics three coordinates, can measure the three-dimensional coordinates of all marks (or coding) at one time. Can be used alone, or integrated with surface scan. When measuring the high resolution digital camera to take pictures from different angles, a series of pictures can be obtained through the calculation of the software, which can get the precise spatial coordinates of the reference points.

Alpha 7000 is a 3D scanner specifically for large objects, its scanning speed is fast, the scanning process is less than 2 hours; the scanning precision, nacelle cover both sides of the 80 screw error value is only 0.012mm.

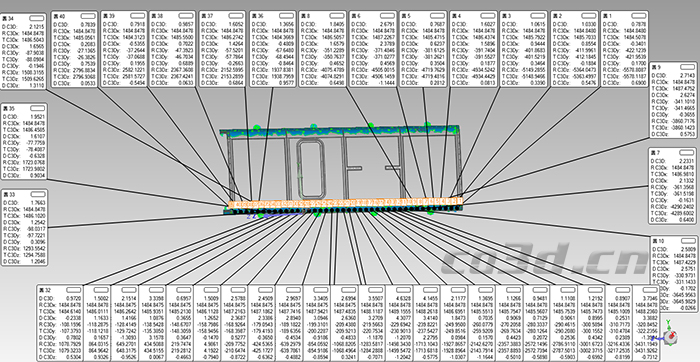

Three dimensional measurement data of wind turbine engine room cover

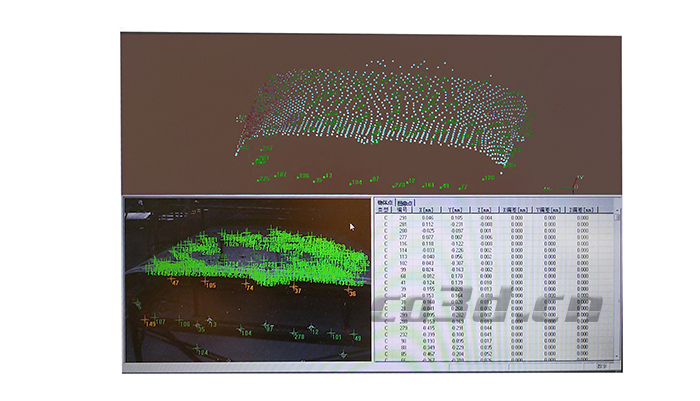

Three dimensional measurement data of wind power generator