In order to improve the qualification rate of aircraft engine impellers, an aircraft manufacturing company entrusted Hualang 3D to make a production inspection program for the aircraft engine impellers they produced. Because the production of aircraft impellers is prone to deformation, the customer needs to obtain high-precision three-dimensional data and perform the analysis with the original digital model. Comparative analysis, testing product processing efficiency pass rate to improve product quality.

Practical problems

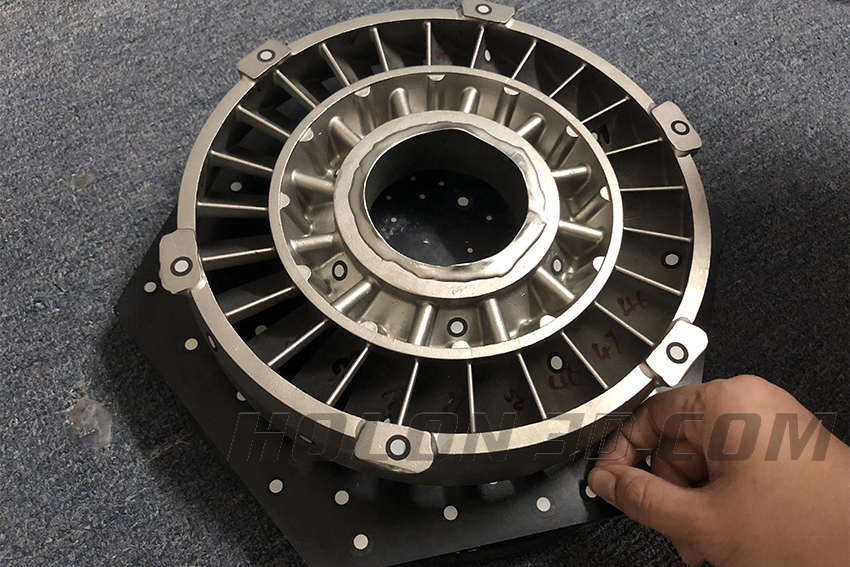

Physical image of aircraft engine impeller

1. The volume of the impeller of the aircraft engine is small, the overall outline is complicated, and the impeller parts have many dead corner shadows. The customer needs to accurately measure the overall three-dimensional data of the part and the customer requires very high accuracy. The traditional measurement method cannot accurately and quickly measure the arc surface data of the impeller. There is no effective measurement plan for the contour and shadow of the blind corner, so that the peers can stop watching.

2. The customer considers the company's later use to save time and human resources, requires high-precision and high-efficiency inspection solutions, and the inspection of finished workpieces does not allow powder spraying, and the impeller is a metal reflective part that brings another big problem to the scanning inspection.

Aircraft engine impeller scene diagram

Holon solutions

Recommended equipment: Handheld 3D scanner A15

Product features: A15, a portable blue-ray handheld 3D scanner independently developed and produced by Hualang 3D, has the following advantages:

◆ Ultra-portable, the body weight is only 0.87kg;

◆ The accuracy is up to 0.020mm, and the resolution is up to 0.050mm;

◆ Blue line laser: adapt to various complex environment measurement tasks such as indoor and outdoor, with stronger anti-interference ability;

◆ High-speed scanning: 480,000 measurements/sec;

◆ Large measurement space, good stability, and a single machine can complete the measurement of super large workpieces;

◆ Almost unlimited 3D scanning, not affected by object size, material, color, etc., without powder spraying;

Scanning scene of aircraft engine impeller

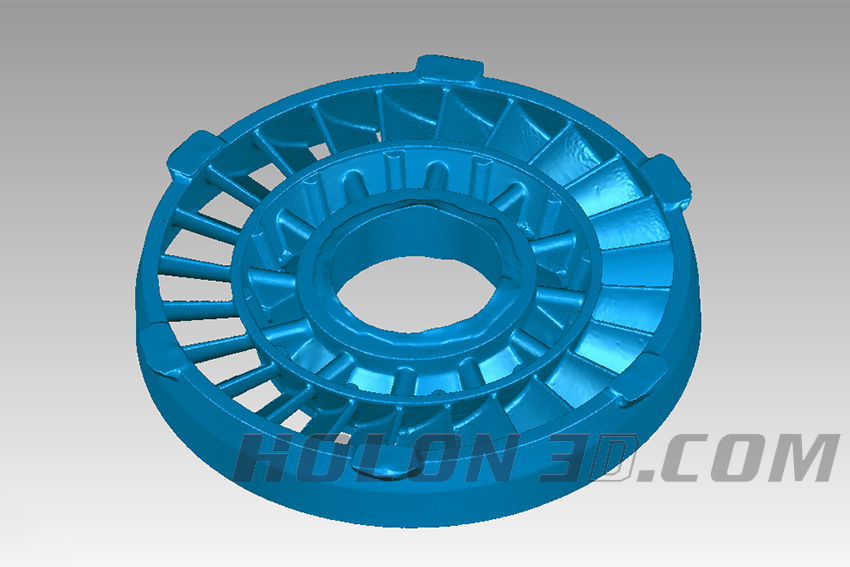

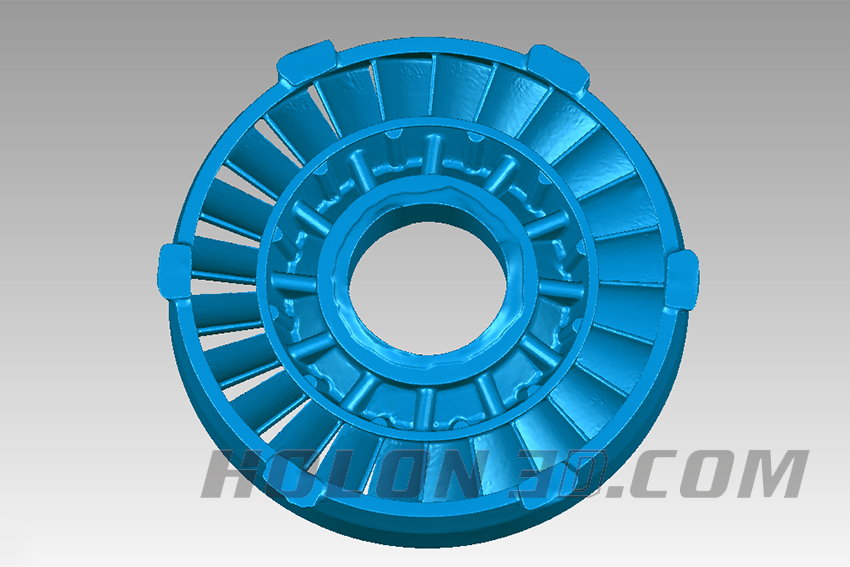

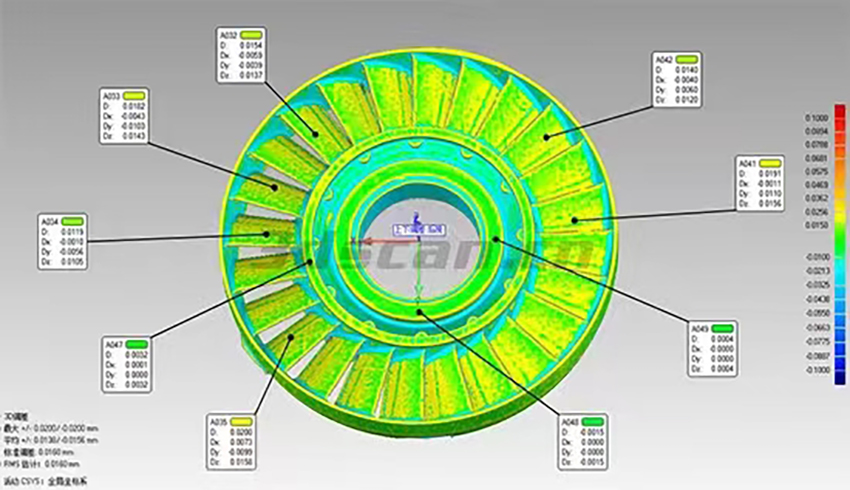

The engine impeller is one of the important parts of the aircraft, so its quality control is particularly important. Hualang 3D technical engineers use the industrial-grade handheld 3D scanner A15 to quickly obtain high-precision 3D data, import the 3D data of the impeller into the 3D inspection software (Gomagic control) to generate 3D data chromatograms, compare and analyze with the original digital model, and inspect the aircraft Whether the engine impeller is qualified, successfully solved the quality problem of product production and provided accurate data support for the secondary design of the aircraft engine impeller.

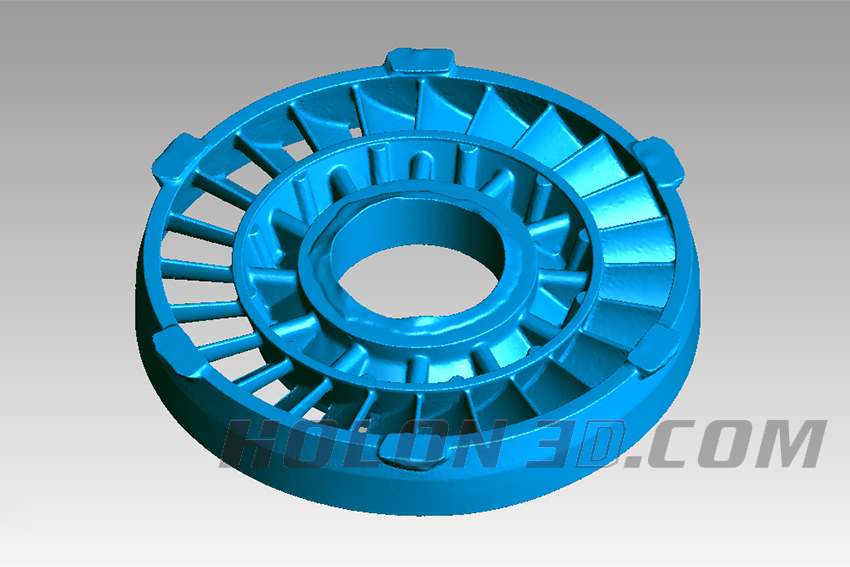

STL data diagram of aircraft engine impeller

The characteristics of aircraft engine impellers are complex, small in size, complex in overall contours, and more shadows in the impeller parts. The handheld 3D scanner A15 has a fast scanning speed. It takes less than 10 minutes to obtain 3D data of aircraft engine impellers, and the data accuracy is as high as 0.02mm. The effect is very satisfactory. The problem of the production quality of the aircraft impeller of the aircraft manufacturing company and the subsequent secondary design has been solved quickly, and the problem faced by the customer has been successfully solved.

STL data diagram of aircraft engine impeller

STL data diagram of aircraft engine impeller

Aircraft engine impeller inspection and comparison data map