The manufacturing process of automobile panel molds is relatively complicated. Good stamping processability can not only simplify the stamping process, but also greatly reduce the capital investment in die manufacturing.

Practical problem

1. The car cover is large in size (3 meters long and 2 meters wide), complex in shape, and inconvenient to move. Traditional measurement tools (such as inspection tools, two-dimensional, three-coordinates, etc.) cannot perform inspection work at all.

2. The customer requires the measurement of the upper and lower mold bonding parts of the automobile cover to optimize the accuracy of the automobile cover mold and improve the production efficiency of the enterprise.

Holon solutions

The automobile cover mold is large in size and complex in shape, so it is difficult to locate and move. Therefore, composite molds are mostly used for covering parts, and the precision requirements of automobile covering parts are very high. After the automobile covering parts are overlapped with the covering parts, the two overlapping surfaces are one surface, and the mutual bonding gap is large, and the quality of the products produced is not good. To meet the standard, in order to solve the problems faced by the enterprise, Hualang technical engineers put forward a solution: use Hualang 3D photogrammetry system (HL-3DP) to take a global picture of the automobile cover mold, obtain the three-dimensional coordinates of the mark points of the inspection parts, and then shoot The finished photos are imported into the software for calculation, and the calculated data is compared with the original digital and analog diagrams, and then the comparison and analysis are performed to obtain the error value between the molds of the automobile covering parts.

Scanning device:

3D photogrammetry system HL-3DP

Features:

●Global coding actuarial registration, suitable for measuring different objects of large, medium and small.

●Control the overall accuracy of the workpiece during the three-dimensional measurement of super large workpieces

●Quickly calculate the precise three-dimensional coordinates of the coding points and marking points on the surface of the workpiece.

●Using alloy target rod, higher stability.

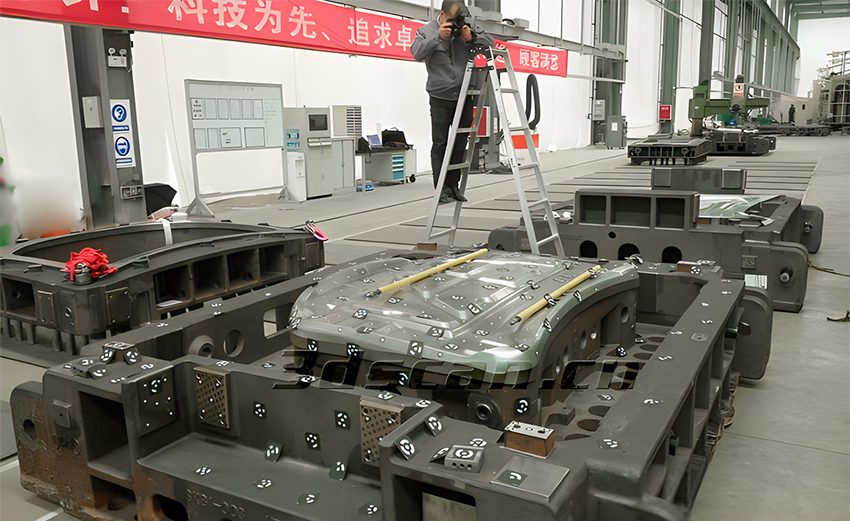

Auto panel mold measurement site

Technical engineers take global photos from different angles

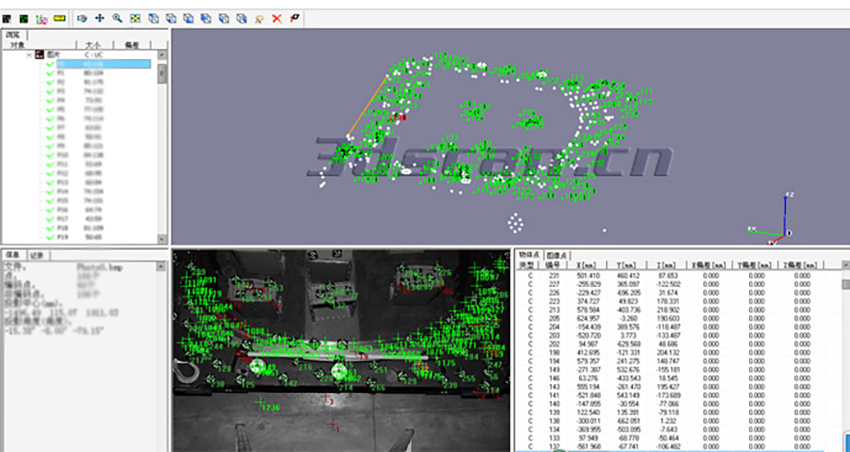

Photogrammetry system software calculates imported photos

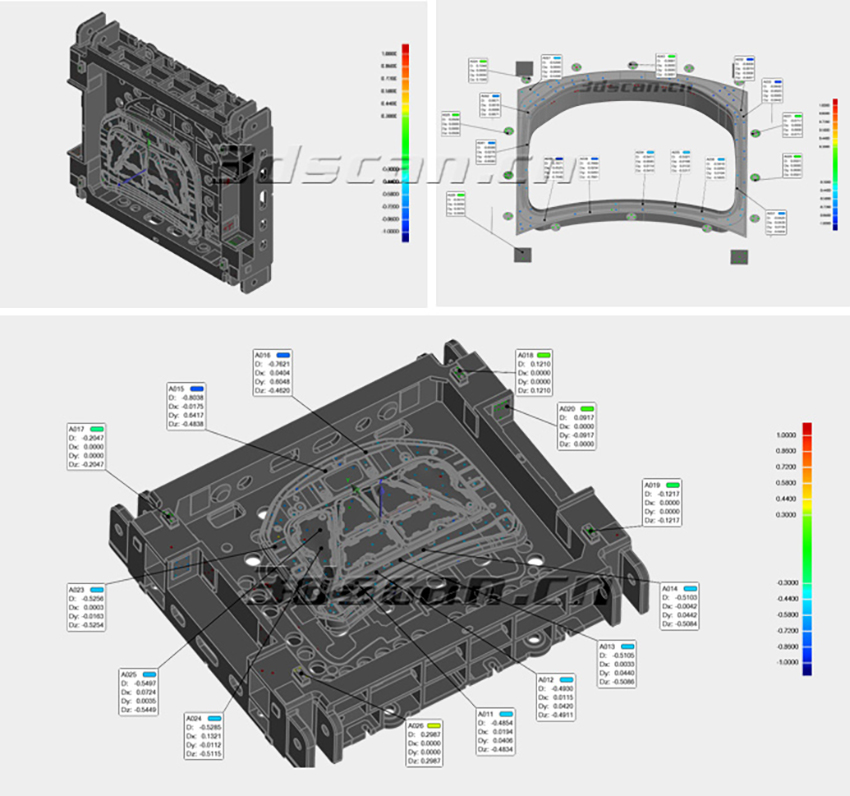

Compare the detection chromatogram with the original digital and analog diagram