When measuring auto parts, it is sometimes necessary to disassemble the parts and scan them separately to obtain the highest accuracy for reverse design or three-dimensional inspection. Sometimes, because of conditions, the parts cannot be disassembled, and they can only be scanned directly on the car. As the first domestic manufacturer to develop and produce a handheld laser 3D scanner, Hualang not only has strong adaptability to the scanning environment, the equipment is easy to operate, and it can also reach industrial-grade high-precision standards.

Practical problems

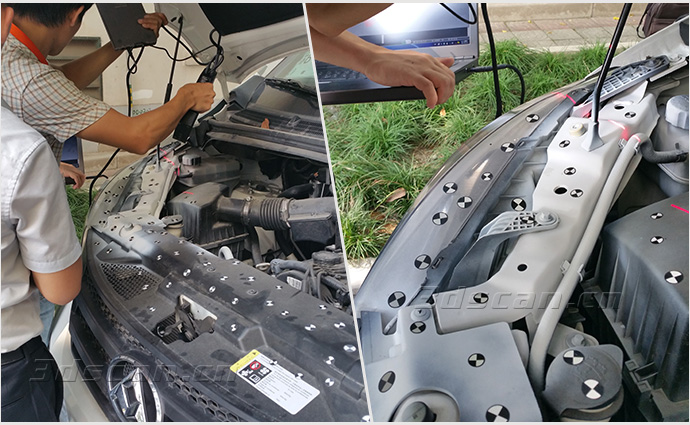

The two sheet metal parts have been firmly fixed in the car engine compartment, and the purpose is to measure the installation position, so it is not convenient to disassemble. Although the camera scanner can scan by raising the tripod, it is quite troublesome to scan due to too many blind spots.

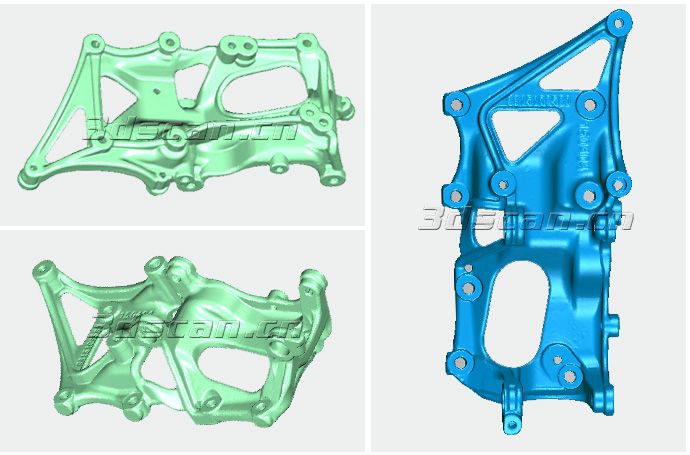

Auto parts have complex shapes and many holes. They are objects that are difficult to scan and require high precision. Common scanners on the market cannot obtain high-precision data.

Holon solutions

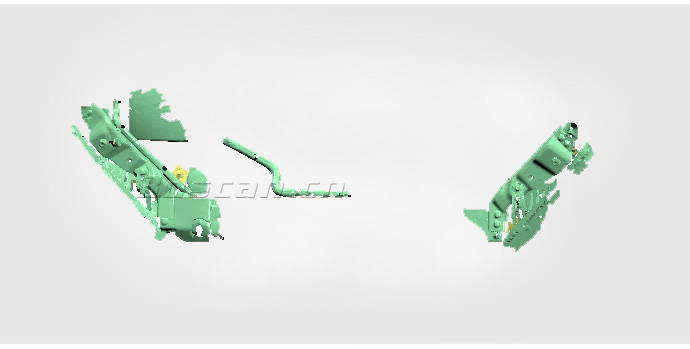

HL-3DH-3M is a handheld 3D scanner independently developed by Hualang technical team for the purpose of convenient scanning. It uses a laser light source and comes with a photogrammetric function. The scanning process is also arbitrary, not limited by scanning speed and scanning sequence. At the same time, it is light in weight and small in size. It is equipped with a DC power supply and a special air box, which is very convenient to carry. The other end of the scanner is connected to a computer, with Hualang's patented scanning software, real-time data transmission and automatic splicing. In less than 20 minutes, the sheet metal parts on the left and right sides of the car's engine compartment have been scanned, and after simple processing, a 1:1 high-precision STL data can be obtained. If the three-dimensional data is compared with the digital model, an intuitive three-dimensional inspection report can also be generated.

Laser handheld scanner scans the scene

Front bumper support point cloud data

Car front bumper support STL data

Auto parts scanning site

The picture shows a precision casting part of Dongfeng Motor. The shape of the part is complicated and there are many holes. If manual measurement is used, the efficiency will be very low and the accuracy will be poor. The finished product is at risk of being reworked. According to customer needs, Hualang engineers recommend the use of a handheld laser 3D scanner HL-3DH-3M. After the quick scan, the data will be imported into the 3D reverse software (Geomagic) for processing, and the processed data will be imported into Pro/E, UG In other mainstream design software, it can speed up mold development with high quality and successfully solve the urgent needs of customers.

3D data of auto parts