Aircraft manufacturing not only facilitates people’s travel, but also reflects the country’s development and strength. Recently, a well-known domestic aircraft manufacturer needs to scan the impeller of aircraft engine components to quickly obtain high-precision three-dimensional data for research and development in the aircraft military industry. , And the development and design of new projects.

Practical problems

The impeller of aircraft engine components is small and complex, and there are many dead corner shadows of the components. Customers need to accurately measure the overall three-dimensional data of the components and the customer requires very high accuracy. If the irregular arc surface of the workpiece cannot be effectively measured, the aircraft engine cannot be measured. The component impeller performs normal inspection and measurement work, which cannot meet customer needs.

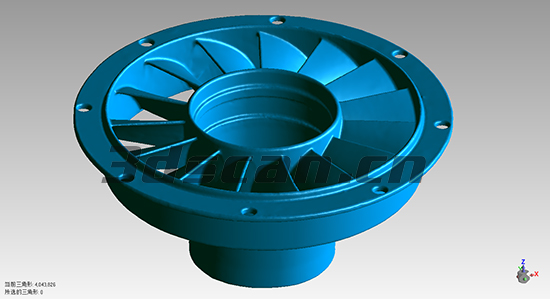

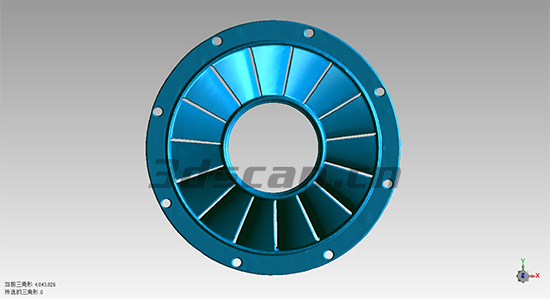

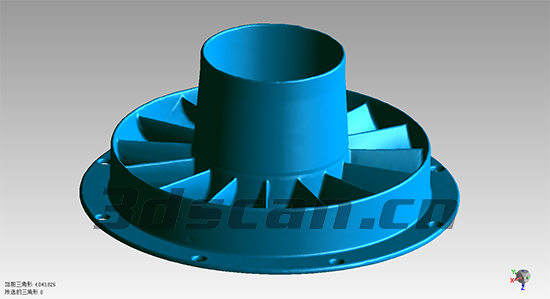

The physical picture of the impeller of the aircraft engine part

Holon solutions

Recommended equipment: camera type 3D scanner HL-3DX

The impeller of aircraft engine components is small and complex, and customers require high scanning accuracy and high speed. Hualang's camera-based 3D scanner HL-3DX is currently the most recognized scanner model in the field of industrial 3D inspection. Its advantage lies in high accuracy and stability. Strong sex.

Use our new 3D scanning technology to obtain 3D data of the impeller of aircraft engine components. It can effectively reduce errors and improve the overall scanning accuracy. The operation is simple and more efficient. Customers also recognized and purchased our equipment.

STL data diagram of aircraft engine parts impeller

STL data diagram of aircraft engine parts impeller

STL data diagram of aircraft engine parts impeller