The plastic intake manifold has the characteristics of light weight, poor thermal conductivity, and low air resistance. At the same time, it is formed at one time during the production process, and the qualification rate is high. Compared with the aluminum intake manifold, the cost is reduced by 20% to 35%. A customer needs to copy the data of a 380×330×180 intake manifold, import the data into the computer for slight modification, and then open the mold to achieve efficient and low-cost mass production.

Practical problems

The intake manifold is a complex structure, not only has many dead spots, but also the shape of the ribs on the surface varies. If an ordinary 3D scanner on the market is used, there may be problems such as failure of data splicing and poor accuracy of stiffeners.

Holon solution

The intake manifold refers to the intake pipe from after the carburetor or throttle body to the cylinder head intake port. Its function is to distribute the air and fuel mixture from the carburetor or throttle body to the intake ports of each cylinder to maintain driving safety. The connection size tolerance requirements of the intake manifold and the engine are very strict, and the installation of the sensors and actuators on the manifold must be very accurate. Therefore, starting from the data acquisition, there is no room for large errors.

Holon3d engineers used an industrial-grade three-dimensional scanner: HL-3DSV+ based on the complex structure of the intake manifold and high precision requirements. It has the advantages of fast scanning speed, small optical distortion, and high scanning accuracy.

Intake manifold after powder spraying and sticking

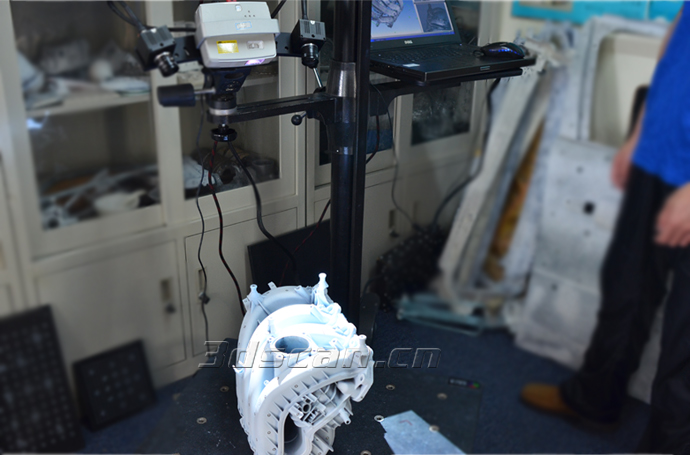

Scan the scene

Scanning steps:

Spray developer (improve the contrast of the background color of the workpiece surface to obtain more complete and better scan data)

↓

Stick mark points (to realize automatic splicing of scanned data)

↓

3D scanning

(One-click shooting, simple operation, changing the angle of the object or equipment, so that the lens can capture every surface of the object)

↓

Point cloud data, STL data (high-precision three-dimensional data, can be transformed into various formats for reverse design)

↓

The data is imported into the machining equipment to process the mold, and the goal is achieved

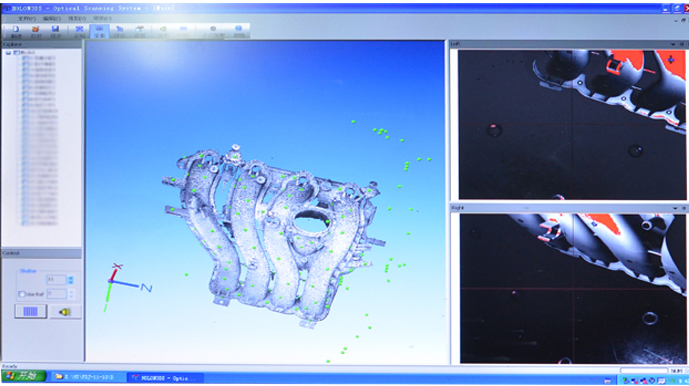

The computer is processing data

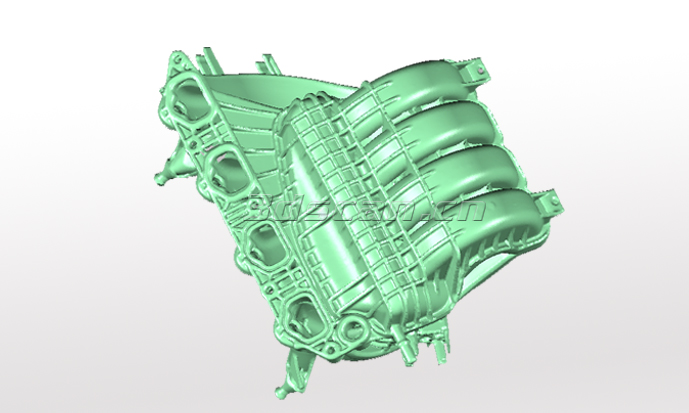

Intake manifold point cloud data

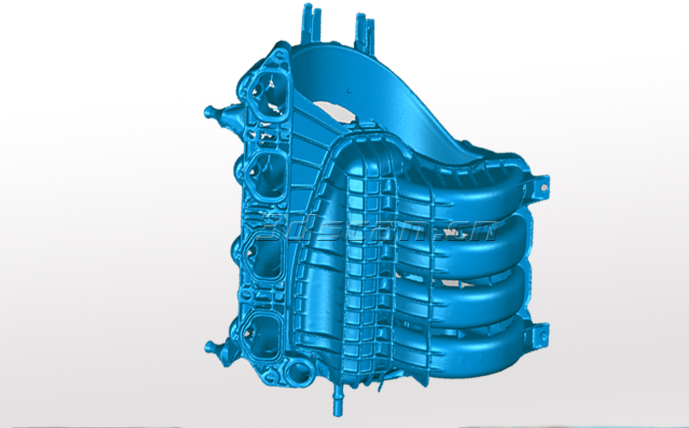

Intake manifold STL data