The manufacture of dentures generally needs to be divided into multiple steps, from the production of the dental model, to the measurement of the dental model, to the manufacture of the denture, and finally to the experimental wearing. The most critical step is the accuracy of the dental model measurement. If the measurement of the dental model is wrong or the accuracy is not high, the result is that the molded denture cannot be worn or the patient feels extremely uncomfortable after wearing it. At the same time, the production method of this kind of denture has a long cycle and low efficiency.

Dental model

Practical problems

1. It is necessary to obtain the high-precision three-dimensional data of the impression of the patient's missing tooth area, abutment and base area, and manufacture the best matching denture with the gums.

2. In traditional denture manufacturing, the three-dimensional data of the dental model is insufficient, which makes the molded denture unable to be worn or the patient feels extremely uncomfortable after wearing. The production cycle is too long and the efficiency is low.

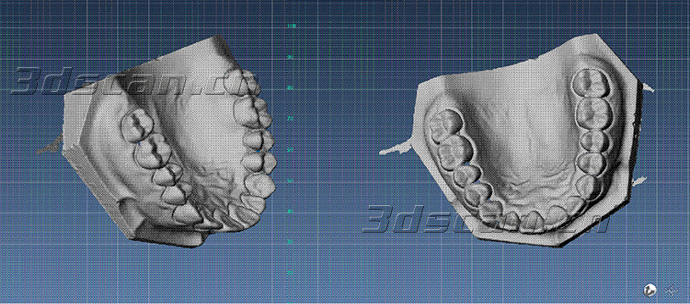

3D Scanning of Dental Model

Holon solutions

1. Preliminary preparations

Spray developer and paste marking points

2. Three-dimensional scanning

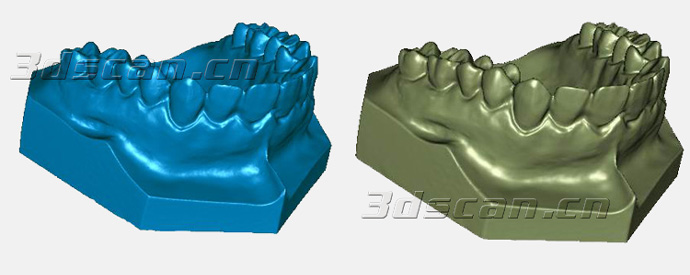

Holon3D scanner HL-3DM can obtain the 3D data of the tooth model, use the reverse design software Geomagic Studio to properly repair and correct the tooth model data, and then input the processed tooth model data into CNC processing equipment or rapid prototyping Equipment to make dentures.

Finally, the doctor or technician can perform fine processing on the denture according to the actual needs of the patient, and then it can be worn. In addition to shortening the treatment cycle and helping patients to recover as soon as possible, it also improves the precision of denture manufacturing to achieve the best cosmetic effect and the most comfortable contact with soft tissues.

Dental model scan STL data map

Tooth scan STL data map