At present, most hospitals rely on imported nuclear magnetic resonance imaging (MRI) instruments, and the manufacturing of precision instruments has become a difficult pain point to overcome in terms of high-precision requirements. Equipment manufacturers need a high-precision detection method to conduct three-dimensional scanning of the shell sample in order to pursue higher accuracy in the manufacturing process of the shell.

Practical problems

Precise instruments and equipment require higher precision. Hualang handheld 3D scanner uses its self height precision scanning to meet customer needs.

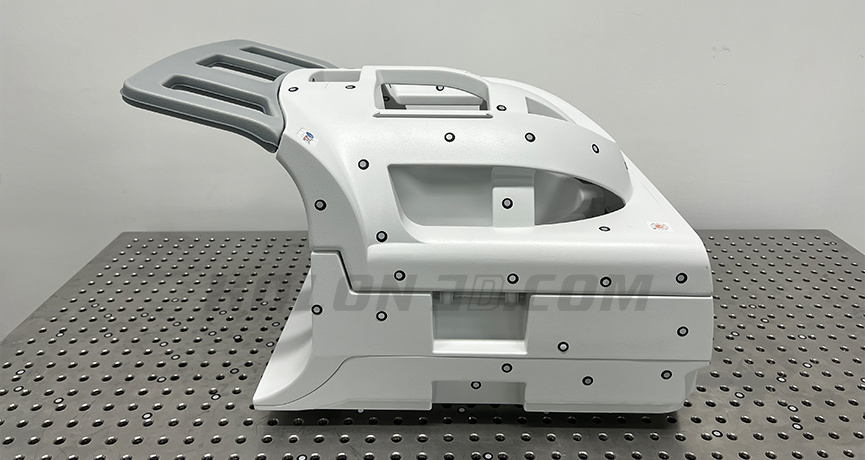

Physical image of the shell of the nuclear magnetic resonance instrument

Physical image of the shell of the nuclear magnetic resonance instrument

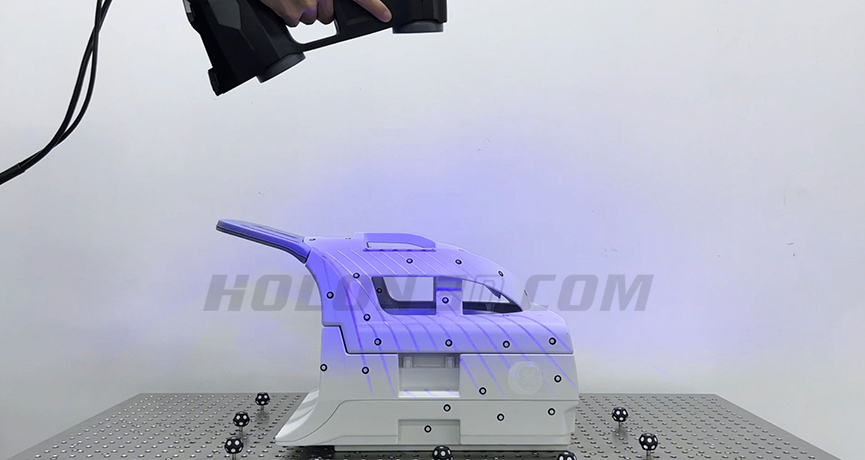

Holon solutions

The handheld blue light scanner HOLON B71 sequentially scans the shell components, achieving industrial grade high precision and minimizing cumulative splicing errors, highly reproducing the overall three-dimensional data of the shell. High precision scanning provides high-precision data support for customer testing and reverse engineering, ensuring the quality of finished products after assembly of nuclear magnetic resonance instruments, and ensuring the normal operation of the instruments in the later stage. The application of three-dimensional scanning further accelerates the pace of independent production of nuclear magnetic resonance instruments in China, and opens up new territories in the field of precision instruments.

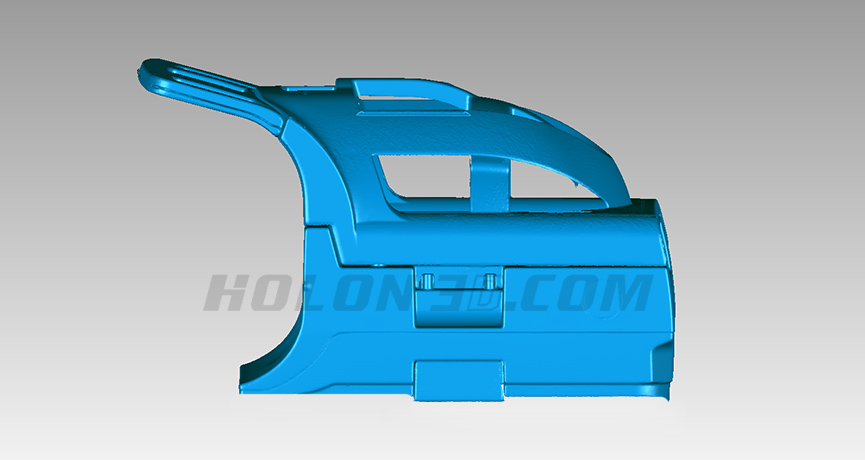

Physical image of the shell of the nuclear magnetic resonance instrument

Physical image of the shell of the nuclear magnetic resonance instrument