With the development of the automobile industry and the revitalization of the domestic automobile industry, the demand for automobile fuel tanks by major automobile manufacturers has shown an obvious growth trend. A well-known automobile manufacturer in Tianjin hopes to scan the fuel tank of the Mercedes-Benz G500 car to obtain high-precision three-dimensional data and then process it with post-processing software to perform product reverse design to shorten the development process of new products.

Practical problems

1. The customer wants to scan the fuel tank of Mercedes-Benz in the factory workshop, so it has higher requirements for the portability and stability of the 3D scanning equipment.

2. The customer's data collection method for the original automobile fuel tank is manual measurement, which has low accuracy and slow speed.

3. The quality of the automobile fuel tank directly affects the overall performance and safety performance of the automobile, and requires high accuracy for the three-dimensional data obtained from the automobile fuel tank.

Holon solutions

According to the problems faced by the customer, Hualang engineers proposed a solution to use the camera-based 3D scanning HL-3DX to scan the fuel tank of Mercedes-Benz G500, and quickly obtain 3D data of the fuel tank of Mercedes-Benz. It not only has high data accuracy and fast scanning speed combined with 3D reverse software. The successful completion of the overall scanning of the workpiece has improved efficiency for the reverse design of later products and the development of new products, saved costs, and satisfied the scanning needs of customers.

Mercedes-Benz G500 renderings

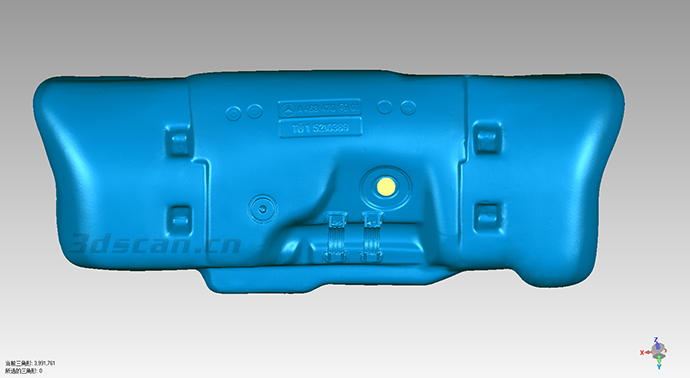

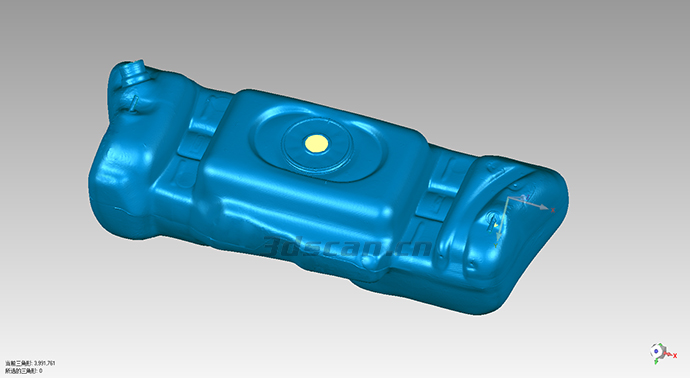

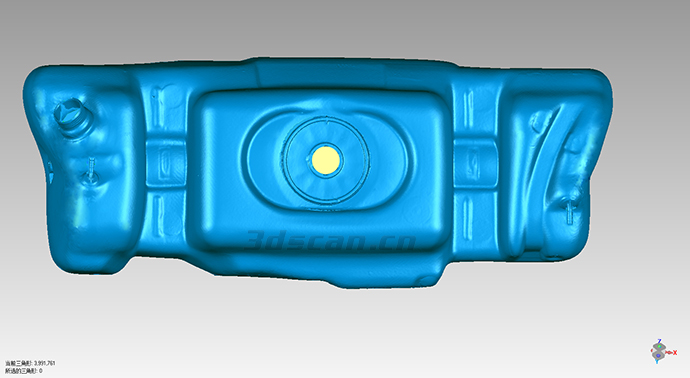

Mercedes-Benz fuel tank STL data chart

Mercedes-Benz fuel tank STL data chart

Mercedes-Benz fuel tank STL data chart