The three-dimensional scanner can scan the car bumper, obtain high-precision three-dimensional data, improve the second development efficiency of the car bumper, and ensure the accuracy of CAD design results.

Practical problem

1. It is very tedious and time-consuming to simply use traditional methods (such as inspection tools, fixtures, three coordinates, etc.) to measure the car bumper, and it is not easy to accurately and quickly measure and detect the shape of the car bumper.

2. Automobile bumper has many curved surfaces and snap parts, and the bumper is relatively large and prone to deformation. It is difficult for general 3D scanners to quickly and accurately obtain the 3D digital model of automobile bumper.

On site scanning of automobile bumper

Holon solutions

The customer wants to further improve the car bumper, save production costs and improve the product qualification rate. Therefore, Hualang 3D engineers provided a professional solution - 3D scanner hl-3dw (to quickly obtain high-precision 3D data of automobile bumper) + reverse design software Geomagic studio (to convert automobile bumper point cloud data into triangular mesh surface data) to assist the company in the secondary design of automobile bumper.

1. Preliminary preparation

Spraying developer: improve the surface background color contrast of the sample to obtain better scanning data.

Paste mark points: make the acquired data be positioned and spliced in the scanning software.

Pre scanning diagram of automobile bumper

2. 3D scanning

Hualang 3D engineers use the 3D scanner hl-3dw to quickly obtain high-precision 3D data of automobile bumper. The three-dimensional scanner has the characteristics of large scanning format, portable design, extremely fast scanning speed, high precision and high stability. It only takes 30 minutes to obtain the three-dimensional data of automobile bumper, with an accuracy of 0.03mm. Using the obtained three-dimensional data of automobile bumper, the secondary design of automobile bumper is accelerated, reliable parameters are provided to other relevant departments, and the production of automobile bumper is accelerated.

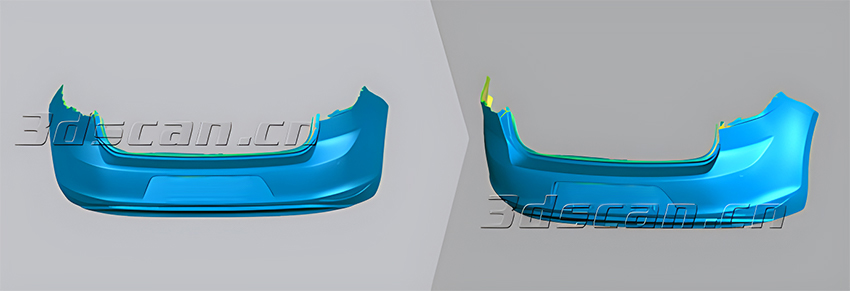

STL data diagram

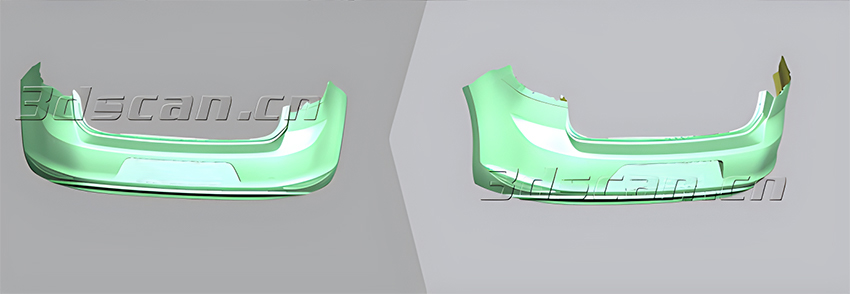

Point cloud data graph