The data collection and 3D surface reconstruction of the existing car seats are carried out by using the Hualang handheld 3D scanner hl-3dh-3m in combination with the reverse design technology. The obtained 3D data are used for modeling and subsequent design, such as rapid prototyping, appearance quality inspection and other applications, which effectively help enterprises shorten the development time of new car seats.

Practical problem

1. the seat area of each model is different, and the amount of design is very large. However, the conventional measurement method takes a long time, which does not meet the expectation of quickly obtaining the three-dimensional model of the car seat.

2. it is required to scan the seats in the car. The space in the car is relatively small, and the traditional measurement method cannot be operated.

Scanning site map of motorcycle accessories

Holon solutions

To measure the seat area of each model, conventional measurement methods cannot meet the needs of customers. Therefore, Hualang 3D technical engineers recommend to use the handheld 3D scanner hl-3dh-3m, which has the advantages of small volume, light weight, simple operation, fast scanning and no external connectionCharacteristics of AC power supply. It can quickly scan the seats in the narrow interior space to obtain high-density point cloud data.

Using the hand-held 3D scanner hl-3dh-3m, the 3D data of car seats can be obtained in only 10 minutes, with an accuracy of 0.07mm. The three-dimensional data of car seats are imported into mainstream reverse software such as pro/e and UG for post-processing, so as to speed up the secondary design of car seats, provide reliable parameters to other relevant departments, ensure that the design results fully meet the production requirements, and speed up the production of car seats.

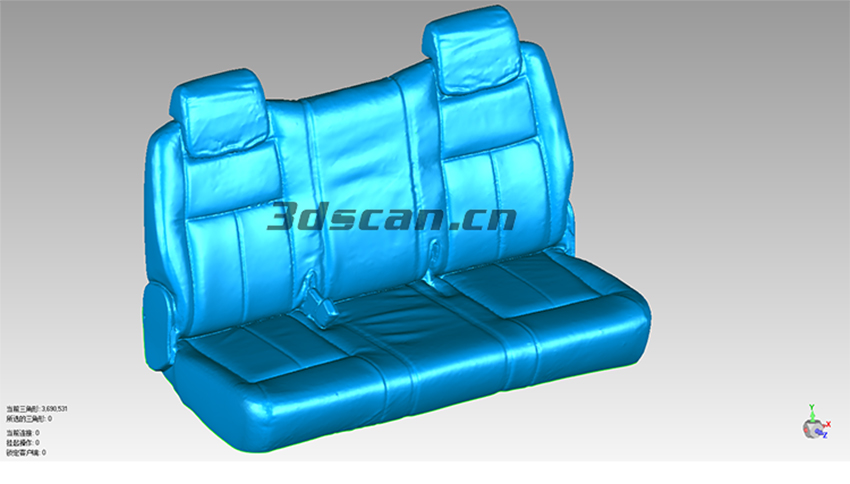

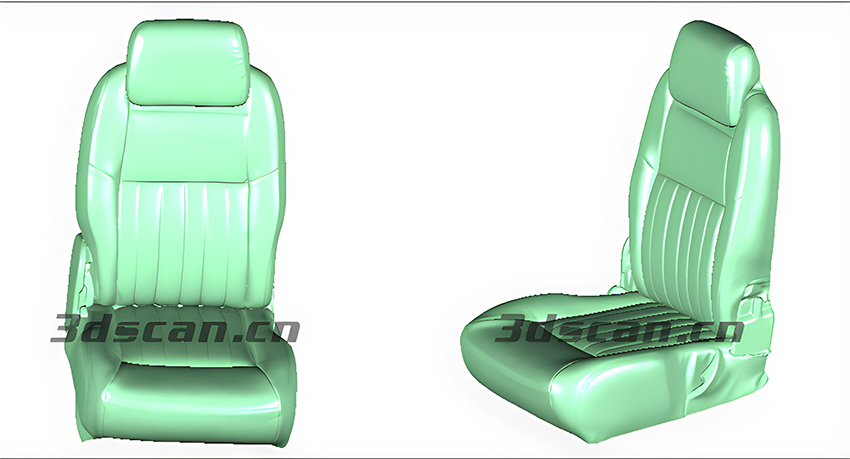

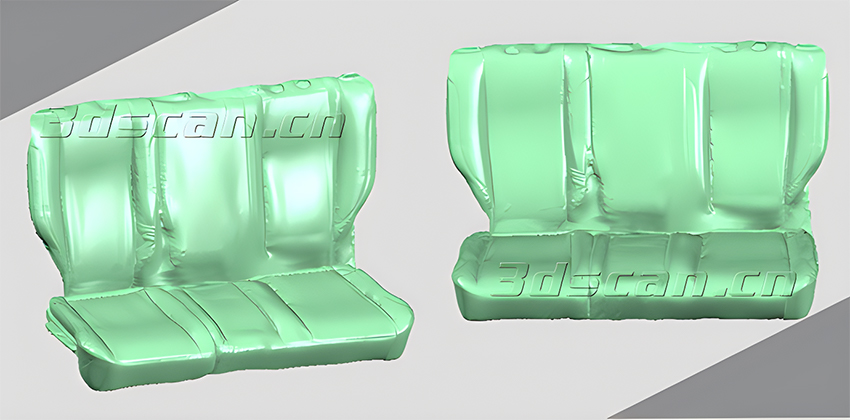

STL data diagram

STL data diagram

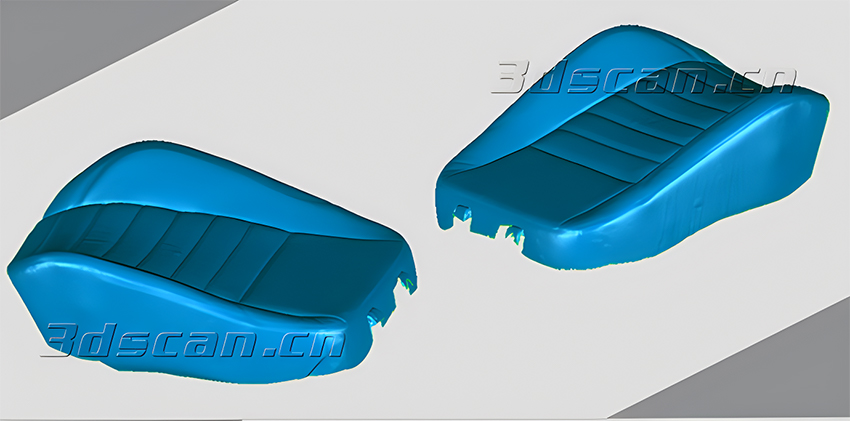

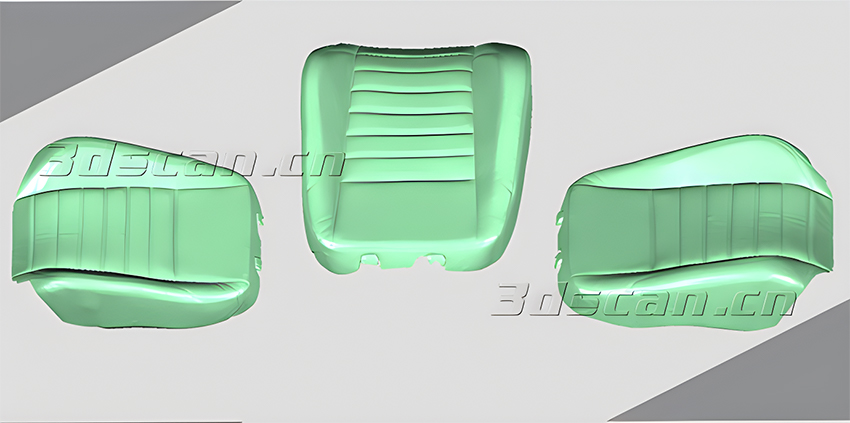

Point cloud data graph

Point cloud data graph

Point cloud data graph