A well-known domestic enterprise needs to obtain 3D data of gearbox for 3D inspection and data comparison and analysis.

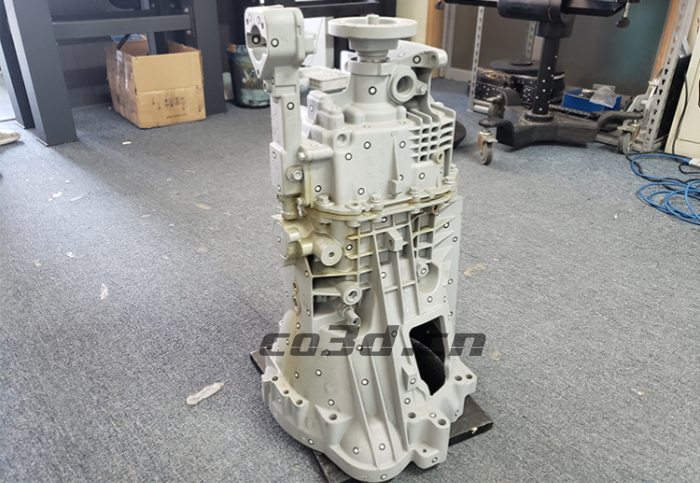

Gearbox real shot

Practical problems

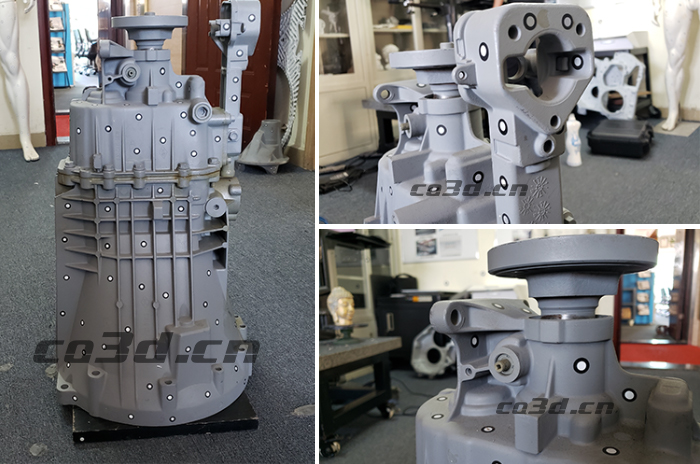

The gearbox has a complex surface and a large number of contour holes. The production process is prone to deformation. The production yield is not high. In order to improve the production quality of the gearbox, three-dimensional data detection is required for the gearbox. The traditional measurement method is not efficient and the cost is too high. Data is not accurate enough to be accurately detected, so quality inspection and quality control issues cannot be resolved.

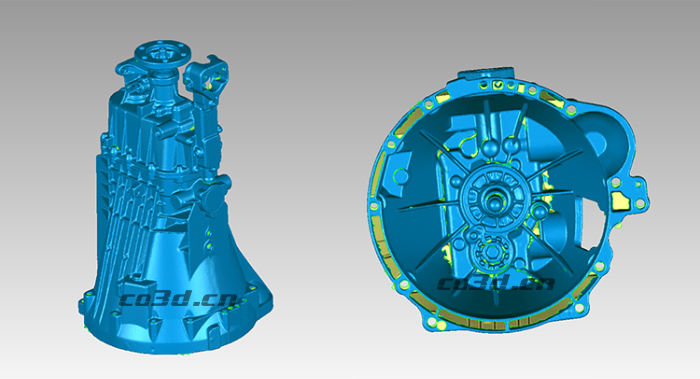

Gearbox detail display

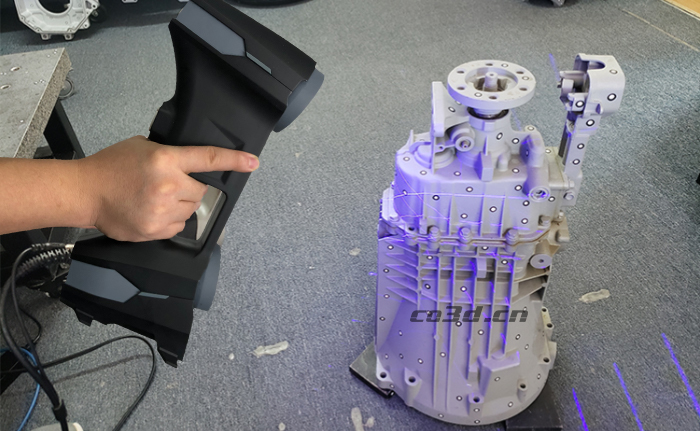

Holon solutions

Using the handheld 3D scanner (HOLON760) to obtain high-precision 3D scan data of the gearbox, import 3D inspection software for detection and analysis, generate color difference analysis chart and error analysis report, thus solving the problem of quality inspection and quality control.

Gearbox site scan

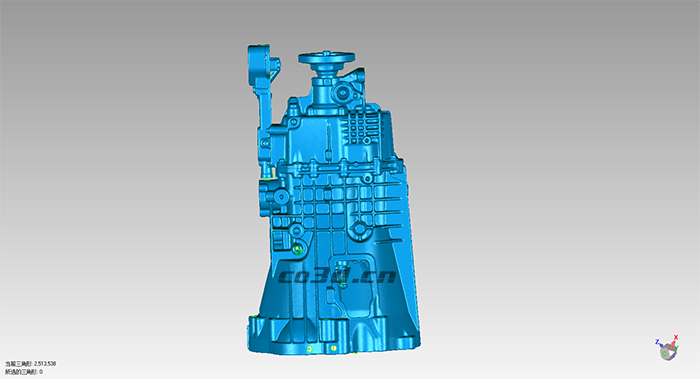

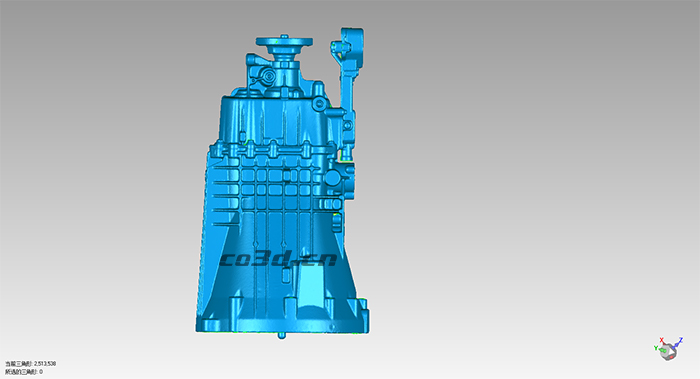

Gearbox STL data chart

Gearbox STL data chart

Gearbox STL data chart