Catalytic converter is the most important off-board purification device installed in the exhaust system of automobiles. It can convert harmful gases discharged from automobile exhaust into harmless gases through oxidation and reduction. The car exhaust is purified. Therefore, the catalytic converter is a very important device in the automotive parts, and it is necessary to pay attention to quality assurance and various aspects of data. A manufacturer needs to perform three-dimensional inspection and analysis on the catalyst to upgrade and improve it later.

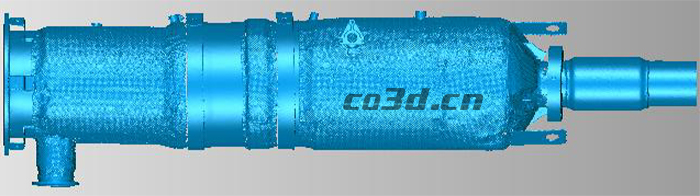

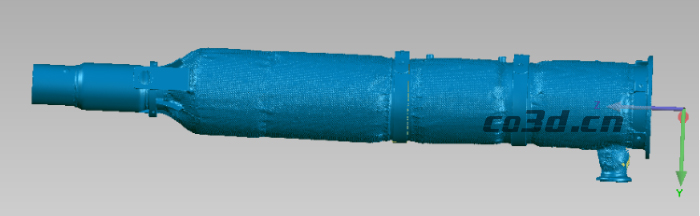

Catalyst scanning site map

Practical problems

The exhaust gas catalytic converter is long, the surface is irregular, the detail features are obvious, the components are different in size, and the customer requires high scanning precision and high speed, and does not consume too much manpower and material resources.

If the traditional three-dimensional scanning method is used, the scanned details are not significant, and the acquired data is not high in accuracy, and cannot meet the needs of the customer, and the consumption time is relatively long.

Catalyst scanning site map

Holon solutions

According to the characteristics of the scanned workpiece, the hand-held three-dimensional scanner HOLON760 is used, and the light source is composed of 7 sets of intersecting laser lines plus an additional laser line for a total of 15 laser lines, and the scanning speed is extremely fast, and the scanning can be completed in a short time. It can also be switched to a single laser scanning mode, which is suitable for scanning deep holes and dead angles, so that the scanning data has high precision, the scanning details are remarkable, the effect is good, and the stability is strong. Lightweight and portable, it can be used in a variety of scenarios, and can be operated by one person, greatly improving work efficiency and saving resources. Quickly scan the scanner to obtain high-precision data, import the acquired data into the 3D inspection software and compare the original data to detect whether the exhaust gas catalytic converter is qualified or not, and provide data reference for the customer's production quality and later design transformation of the catalyst. I was very satisfied with the secondary scan effect.

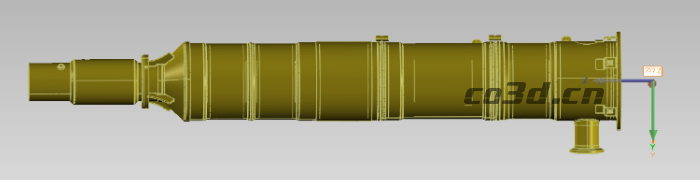

Catalyst STL data chart

Catalyst STL data chart

Catalytic data map