The new energy electric vehicle market has formed a significant market space under the state's strong subsidy policy and support policies. In the consumer sector, the replacement of traditional fuel vehicles with electric vehicles will become a trend. Electric vehicles are an alternative to traditional fuel vehicles for home use, but electric vehicles cannot meet the diverse needs of consumers. As the traditional automotive industry system is very mature, electric vehicle manufacturers hope to modify the existing products from design to product through 3D scanners.

Practical problems

1. A company needs to use a camera-type 3D scanner to convert electric vehicles from traditional fuel vehicles, avoiding large-scale capital investment, and at the same time, the development cycle is short, which ultimately reduces the cost of electric vehicle retrofits.

2. Using the camera-type 3D scanner to perform three-dimensional scanning of the electric vehicle indoors, the customer requires fast access to the fuel vehicle surface 3D data, and the accuracy of the 3D scanning data is high.

Holon solutions

The customer requires a camera-type 3D scanner to scan the entire vehicle. The scanned 3D data directly affects the electric vehicle modification design, and the required scanning accuracy is relatively high. Holon 3D technical engineer uses the top-loading product 3D scanner α7000 to scan the car's 3D data, and carry out the reverse design and development of the car. The 37000 scanner α7000 cumulative scanning precision is very high, the single machine can complete the workpiece scanning about 4m, using carbon fiber components, It has strong thermal shock resistance and small thermal deformation coefficient, which ensures higher scanning accuracy, stronger stability and high efficiency. It scans a car for ≤ 2 hours.

Mercedes-Benz car scanning scene physical map

1. Preparations in the early stage

Spraying the developer: Improve the contrast of the surface of the sample surface, and the 3D scanner can better obtain the 3D scan data of the car.

Paste mark points: The acquired 3D scan data is positioned and stitched in the scanning software.

Mercedes-Benz car site scan

2, 3D scanning

The 37000 scanner scans the car at a fast speed. It takes only about 2 hours to obtain the external 3D data of the car. The integrated scanning accuracy is ±0.04mm/4m. The 3D scanner α7000 uses extrapolation multi-frequency phase shift grating technology, code point calibration technology and fully automatic splicing technology. The car 3D scan data is imported into 3D reverse software (Geomagic) for processing, and the processed data is imported into mainstream design software such as Pro/E and UG to carry out reverse design of the car.

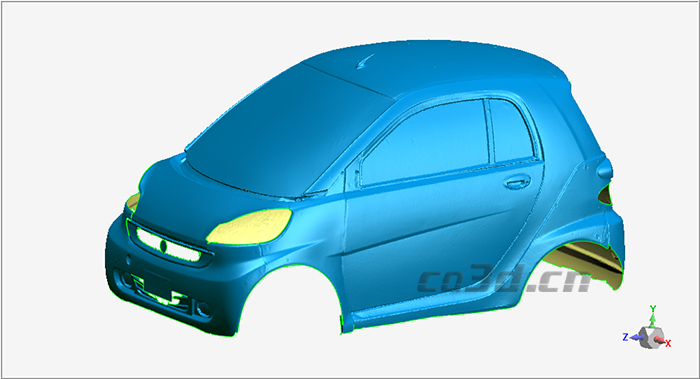

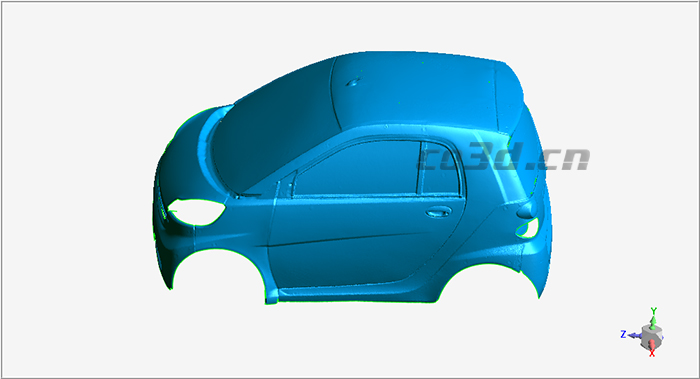

Mercedes-Benz STL data chart

Mercedes-Benz STL data chart

Mercedes-Benz STL data chart