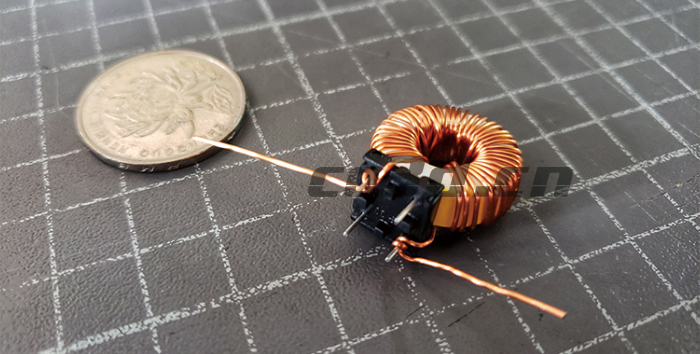

A coil usually refers to a wire winding in a toroidal shape, which is a guide wire that is wound one by one, the wires are insulated from each other, and the insulation tube may be hollow, or it may include an iron core or a magnetic powder core. The inductance of the coil is related to the presence or absence of a magnetic core. Inserting a ferrite core into an air-core coil can increase the inductance and improve the quality factor of the coil. Customers want to obtain accurate coil data and apply it to automated equipment to automatically identify data for screening.

Coil live scan

Practical problems

The overall volume of the coil is small, and the winding wire is thin, and the wire is wound around the insulation tube one by one. There are many details in scanning. Using traditional scanning methods, it is difficult to obtain complete data.

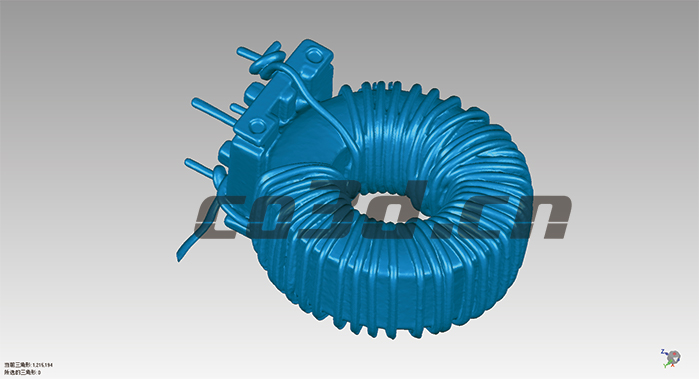

Coil STL data chart

According to the customer's later application requirements, the scanning accuracy is high, the coil data must be complete, and the detail scanning effect is better. When imported into the production line, it can effectively identify unqualified coils for elimination.

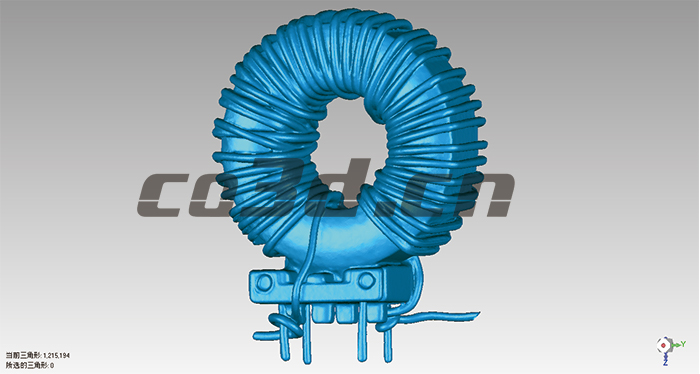

Coil STL data chart

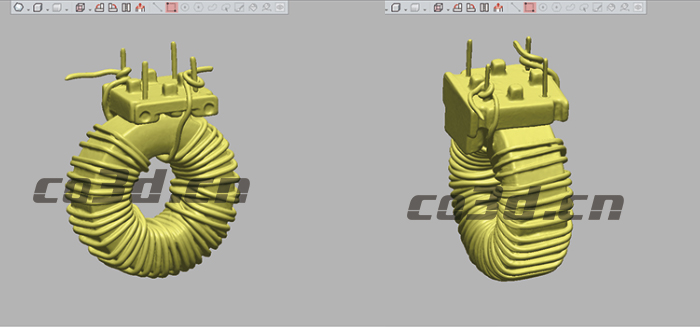

Coil STL data chart

Holon solutions

For scanning such small samples, we also have equipment that can scan specifically to provide customers with convenient solutions. Our company uses a photo-type three-dimensional scanner HL-3DM to scan the coils in a comprehensive manner, and take a picture one by one. The connected computer will automatically splice and generate data with high accuracy.

Coil IGES data graph

The scanning range of the device can be adjusted according to the size of the scanned object. The lens has binocular and four objectives. The operation is simple, easy to disassemble and carry, and the scanning speed is fast. The customer is satisfied with the data and the scan data is complete. The data can be used in the later production line to identify the unqualified coils for elimination, which can improve the quality and service life of the product. At the same time, it can reduce manual inspection and improve work efficiency. Speed up production.

Coil IGES data graph