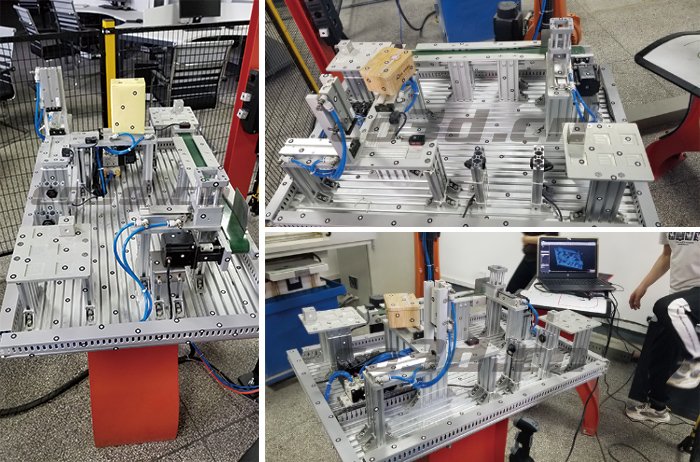

The automated machine system brings great convenience. It is used in conjunction with robots for path planning. Good path planning is the key to affecting the efficient operation of the robot production line. On the basis of pre-judging the robot working path, by establishing a robot space coordinate system, The method and influencing factors of the robot's initial pose and optimal path selection are analyzed. Check whether the robot path planning method meets the actual production requirements.

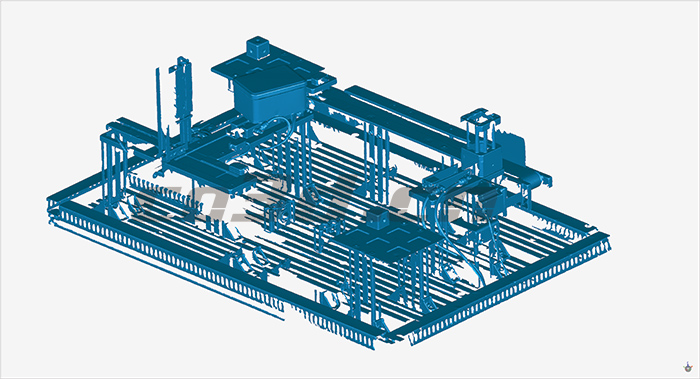

Real production diagram of automated production line

Practical problems

Because it is for path planning, it has high requirements on all links of the automated production line. It can be used in conjunction with the robot to avoid errors. Therefore, it requires high spatial coordinate data by scanning. The traditional method of fixed scanning is not a very convenient scanning operation. The scanning process is difficult, it takes a long time, and it is impossible to obtain effective coordinate information.

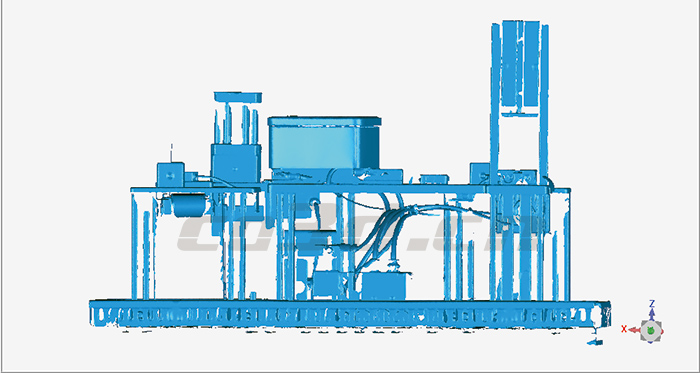

On-site scanning diagram of automated production line

Holon solutions

After understanding and synthesizing our past experience, we use our high-precision, fast scanning and strong stability of the handheld 3D scanner HOLON751. The handheld can be rotated at random to scan from different angles and positions, and multiple laser line modes can be switched The single laser scanning mode is suitable for scanning deep holes and dead corners. There is also a fine mode, which can scan small features and greatly improve data accuracy. And it is simple to use and easy to operate.

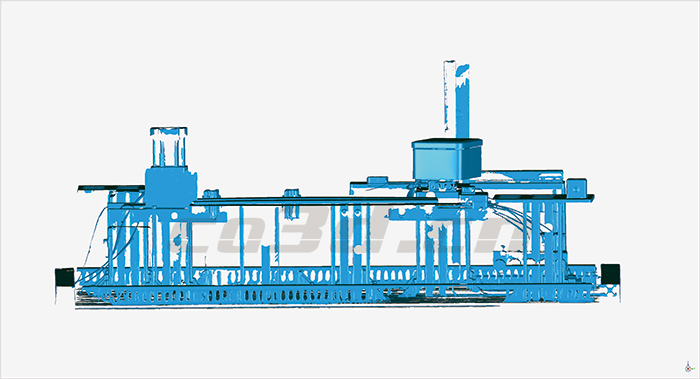

STL data graph of automated production line

STL data graph of automated production line

Import the scanned data into the 3D inspection software for analysis and obtain high-precision spatial coordinate data reports. So as to solve the problems faced by customers in this aspect, provide effective coordinate values, have important reference values in cooperation with robot design, and accelerate the progress of the project.

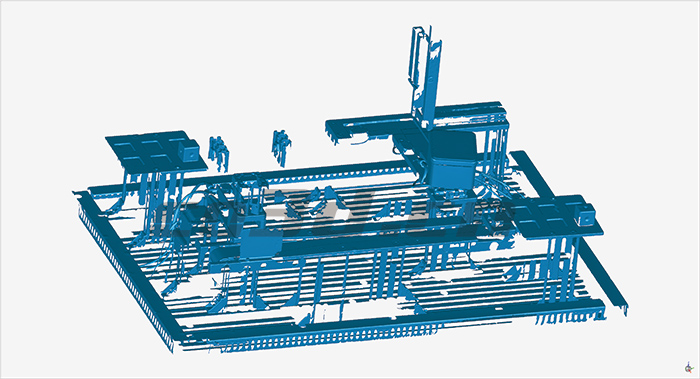

STL data graph of automated production line

STL data graph of automated production line