A large international airline company needs to scan the aircraft hood mold to obtain high-precision three-dimensional data, so as to repair and redo the aircraft hood to save cost and time, and provide effective data support for later mold opening processing.

Practical problems

1. Due to the large volume of the aircraft hood mold and the inconvenience to move, the mold itself has many curved surfaces. The customer requires that the overall accuracy of the aircraft hood mold is high. When measuring with ordinary three-dimensional scanning instruments, the cumulative error will be too large. How to eliminate the impact of the error? Is the biggest problem facing.

2. If the efficiency and accuracy of traditional measurement methods are too low and the accuracy is not high, complete and accurate three-dimensional data cannot be obtained in a short time, so that subsequent work cannot be carried out quickly, and it is really difficult for the later reverse repair and modeling . Waste too much human and material resources.

Holon solutions

In response to the series of problems faced by enterprises in scanning aircraft hood molds (large volume surface accuracy requirements, in order to eliminate scanning cumulative errors and complete stitching, etc.), Hualang 3D technical engineers put forward a solution: use our camera-based 3D scanner HL-3DS+ and 3D photogrammetry system HL-3DP can be used together to complete the scanning of super large workpieces, obtain complete and accurate 3D inspection data, and it is time-consuming and convenient to operate. It saves a lot of manpower, material resources and time, and successfully solves the problems faced by customers. problem.

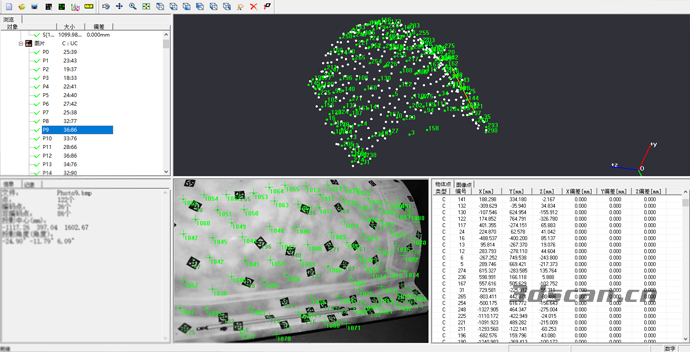

Aircraft engine hood mold site diagram

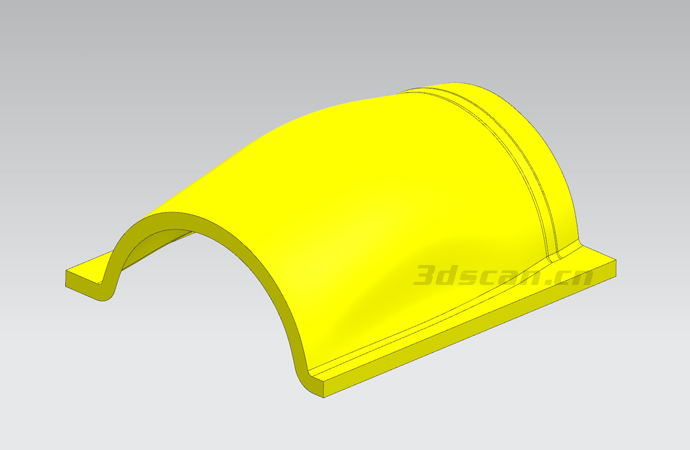

STL data diagram of aircraft hood mold

STL data diagram of aircraft hood mold

Digital Model of Aircraft Engine Cover Mold

Engine cover mold photogrammetric data chart