Holon3d engineers use handheld and camera-type three-dimensional scanners to scan the grinder and grinder parts to obtain accurate three-dimensional data for modification design and subsequent quality inspection.

Practical problems

1. The surface of the grinder is convex and there are many curved surfaces, and the efficiency of using traditional measuring instruments is very low.

2. The structure of the parts of the grinder is complex, there are many grooves, the traditional measuring method is slow and it is impossible to obtain its accurate three-dimensional data.

Scanning scene of grinder

Holon solutions

Grinder is a machine tool that uses abrasive tools to grind the surface of the workpiece, with more curved surfaces and more complex structure. In response to the problems faced by customers, Hualang 3D technical engineers use handheld laser 3D scanners and 3D scanners HL-3DSV+ to quickly obtain high-precision 3D data of the grinder + reverse design software Geomagic Studio (convert the grinder point cloud data into a triangulation network Grid data) + Pro/E, UG and other mainstream design software for post-processing to speed up the secondary design of the grinder. The processed data can be imported into the inspection software to perform detailed analysis of object features, such as hole position, contour, curvature, etc., and at the same time capture and reflect the shape and position deviation of the profile. The Geomagic Qualify inspection software can automatically align the coordinate system of the measurement data with the CAD data, so as to achieve rapid comparison inspection and quality control.

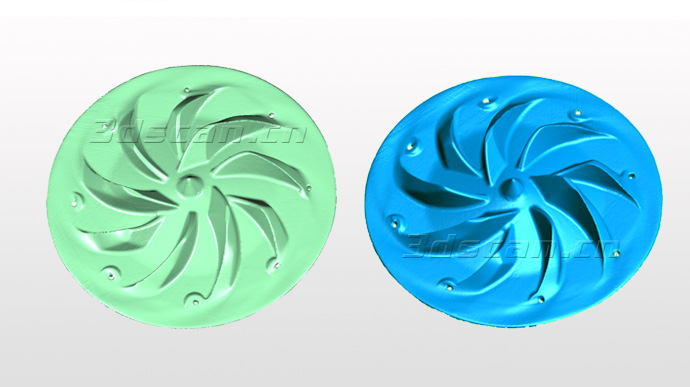

Grinding machine scan data graph