A famous Motor Manufacturing Co., Ltd. is a large enterprise specializing in the production of large and medium-sized, high and low voltage, AC and DC motors. It is a systematic power system provider integrating motor design and manufacturing, electrical control, machining, mold, casting, transportation and other automation projects.

Practical problems

1. The motor manufacturing company undertakes the custom-made motor parts business. Now it is time to take the prototype back from the customer's production site, use the traditional measurement method to obtain the size data of the object, carry out the secondary design according to the data, and then carry out the production. Because of the long cycle and low efficiency of this method, it can not meet the production demand of the current market.

2. Using traditional measurement methods, only partial data of motor parts can be obtained. It is impossible to measure curved surfaces and large radian data, resulting in incomplete data volume, resulting in inaccurate drawing of motor parts, high defect rate, and wasting a lot of manpower. , Material resources, and the quality of motor accessories are not up to standard.

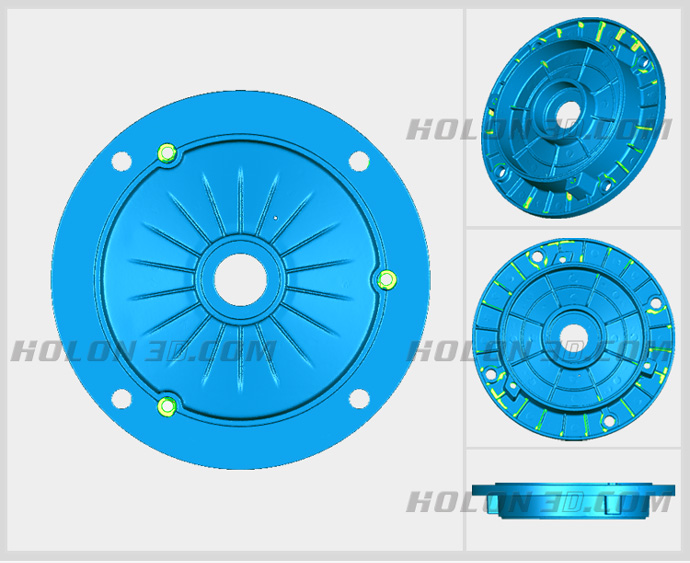

On-site scanning of motor parts and point cloud data map

Holon solutions

According to the problems faced by the motor company, Holon3d technical engineers used 3D scanner HL-3DX (quickly obtain high-precision 3D data of motor parts) + reverse design software (according to the high-precision 3D scanner obtained by the 3D scanner). Three-dimensional data for secondary design) to speed up the production process of motor parts.

The three-dimensional scanner HL-3DX has a small appearance and is easy to bring to the production site. It only takes 10 minutes to obtain the three-dimensional data of the complete motor accessories, and the scanning accuracy is up to 0.02mm. Import the high-precision three-dimensional data obtained by the three-dimensional scanner into the design software, reconstruct the motor accessory model according to the three-dimensional data obtained by the three-dimensional scanner, and convert the model into CAD data for processing. After adopting the solution provided by Hualang 3D technical engineers, the production efficiency of motor parts is greatly improved, thereby solving the problems of motor parts modification and production quality inspection.

Scanning data map of motor parts