In order to ensure the normal processing of the product, Hualang engineers use a three-dimensional scanner HL-3DX+ to scan the upper and lower molds of the product to obtain three-dimensional data for quality inspection and subsequent design modifications.

Practical problems

The traditional mold inspection method is to detect the local surface accuracy of a single part of the mold to determine whether the part surface is consistent with the product design surface curvature. However, after the final mold installation is completed, the weight of the mold makes it impossible for the three-coordinate machine tool to detect it, and it is impossible to intuitively reflect the accuracy of the overall surface of the mold, and then it is impossible to judge whether the mold processing is completely consistent with the product design.

Many other measuring equipment also have cumbersome movement problems. These equipments are obviously time-consuming and labor-intensive to measure medium and large molds in all directions. If the mold inspection results are not accurate and detailed, it will directly cause the company to delay and repair molds, and the inserts will be scrapped and reprocessed, causing great losses and waste. Therefore, a detailed and accurate mold inspection report is required, and timely response measures are taken to ensure that the production quality of the product meets the expected standards.

Scene scan of tiger orchid

Holon solutions

The mold has more curved surfaces and more complex shapes, which makes mold design more and more difficult, and the design time also increases. In response to the problems faced by customers, Hualang 3D technical engineers use 3D scanner HL-3DX+ (quickly obtain high-precision 3D data of Tiger Orchid mold) + reverse design software Geomagic Studio (convert the Tiger Orchid mold point cloud data into a triangular grid Surface data) + Pro/E, UG and other mainstream design software for post-processing to speed up the secondary design of the tiger orchid mold.

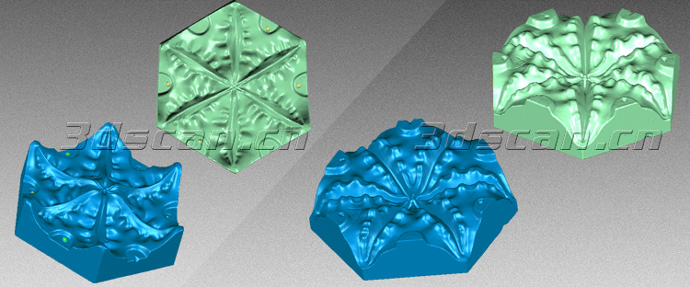

Tiger orchid scan data graph

Obtaining the 3D data of the tiger orchid mold is widely used in subsequent applications:

1. Product improvement;

2. Product quality comparison;