Forklifts play a very important role in the logistics system of enterprises and are the main force in material handling equipment. Widely used in various departments of the national economy such as stations, ports, airports, factories, warehouses, etc. Therefore, in the past few years, the demand for forklifts in China has been growing at a double-digit rate every year.

Practical problems

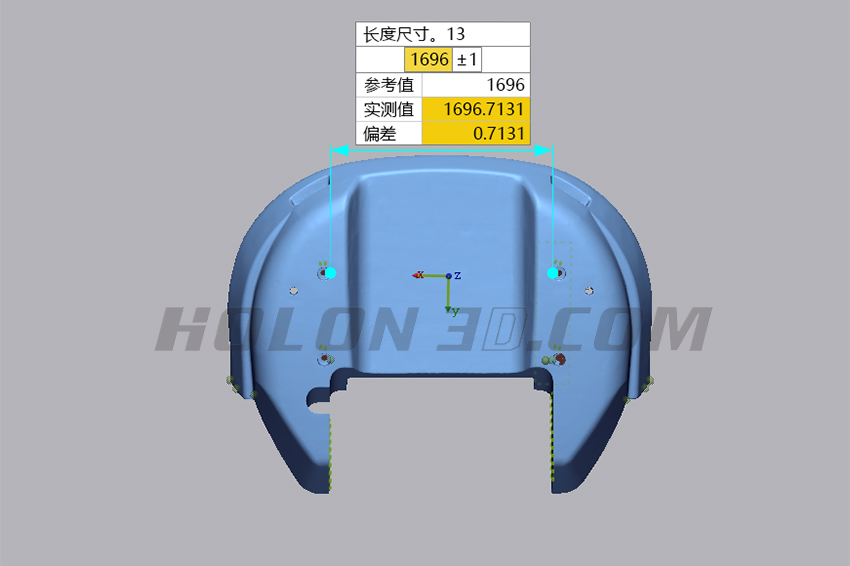

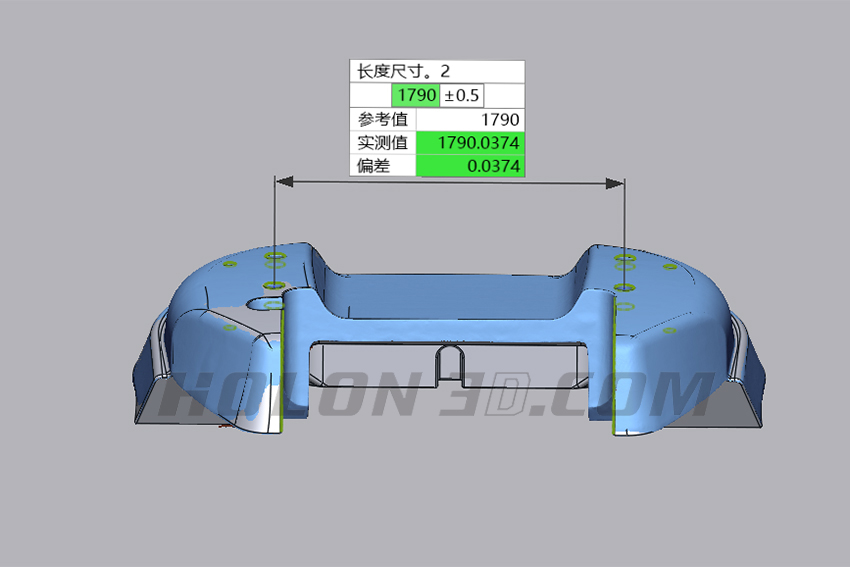

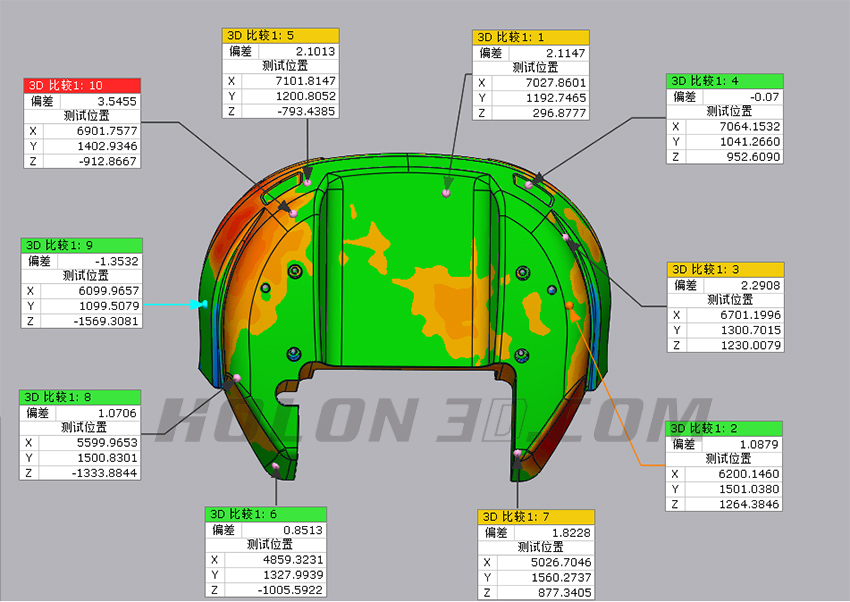

1. The customer needs to conduct a three-dimensional inspection of the rear hood of the forklift and measure the dimensions of the installation holes. High data accuracy

2. The workpiece is 2.5 meters wide, weighs 15 tons, has a large volume, and has an irregular surface with many curved surfaces and hole positions

3. Traditional detection methods are slow to manually measure, with inaccurate data, and many parts cannot be effectively measured, which can easily lead to secondary errors.

Holon solutions

Faced with scanning difficulties, Hualang engineers propose to use a handheld 3D scanner HOLON B71 to collect 3D data on the workpiece. First, a large-scale comprehensive scan is performed, and then the scanning mode is switched according to different parts. It is suitable for various complex application scenarios, with fast scanning speed and high accuracy. Quickly obtained 3D data of machined partsMeasure the size of the installation position to improve work efficiency and meet customer needs.