The customer is a well-known fan manufacturer integrating production and sales, and needs to scan and compare the fan impeller. In order to meet the market demand and improve the competitiveness of the enterprise, the customer decided to abandon the traditional comparison method and introduce a new scanning comparison method. The customer learned that Hualang 3D is the first handheld scanner manufacturer in China, which can quickly and accurately obtain detailed 3D scanning comparison results, analyze whether the products are qualified, and improve product quality and the efficiency of detection and comparison.

On site physical drawing of fan impeller

Practical problems

1. The overall contour of the fan impeller is complex, and the surface is composed of curved surface, radian and other structures. The blade part is easy to cause dead angle shadow. The customer needs to be able to accurately measure the data of the impeller with high accuracy. However, the scanning work is difficult.

2. If the traditional inspection methods (such as inspection tool, fixture, three coordinates, etc.) are used, the manufacturing method is difficult, it will consume a lot of manpower and time, and the data will be incomplete. Many dimensions and geometric features cannot be measured effectively, which is easy to produce secondary errors, affecting the production quality and production efficiency of the product.

Scanning site drawing of fan impeller

Holon solutions

For the problems faced by customers, according to the previous experience of Hualang 3D, when customers put forward their needs, they can quickly think of feasible solutions. Mark points shall be pasted on the scanned samples to facilitate positioning and splicing. We use our hand-held 3D scanner holon771 to quickly and comprehensively scan the samples. The scanner has extremely fast scanning speed and high measurement accuracy of a single machine, making it easy to scan large and medium-sized objects. Moreover, it can be visualized in real time, and the scanning part can be seen on the computer screen, which can be used to make up the missing parts, which is convenient and practical.

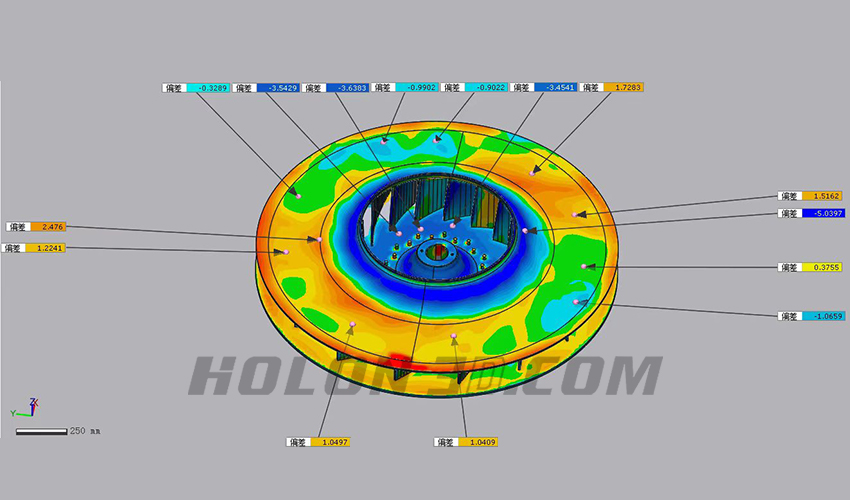

Scan to obtain high-precision data, import the three-dimensional data into the three-dimensional software for processing, analyze the data, and check whether the impeller is qualified or where the existing problems are. The detailed scanning processing effect is good, which improves the product quality and inspection efficiency, and also provides reference data for later product development.

STL data diagram of fan impeller

Comparison and analysis diagram of fan impeller