Holon3d 3DH-3M handheld 3D scanner, the first in China (the first R&D manufacturer), Hualang handheld 3D laser scanner technology is internationally leading, this product has been widely used in the field of reverse engineering and 3D inspection, using the new handheld -Style design, light weight (950g), easy to carry; ready to use, no AC power supply; product with self-calibration function (module), it uses red line laser, has two industrial cameras, and uses angular marking points when working , Used in conjunction with scanning software, supports photogrammetry and self-calibration technology. Especially suitable for on-site 3D scanning, field 3D scanning, 3D scanning of large workpieces, 3D scanning without AC power supply, etc.

Holon3d 3DH-3M handheld 3D scanner uses a 635nm red line laser to scan multiple images of the object before and after the deformation through the red laser, calculate the 3D coordinate values of the key information points on the object surface, and obtain the object deformation data, which can be widely used Application: automobile transportation, heavy equipment manufacturing, aerospace, marine engineering, new energy. Scanning range: 0.1~4 meters. The use of a new type of corner markers has higher positioning accuracy than the commonly used circle markers in the industry. Synthetic scanning of markers and free-form surface scanning. It can quickly and conveniently carry out product shape quality inspection and reverse design of complex workpieces.

Application case: Front-end scanning of EMU

Facing problems:

China is in a critical period of coordinating urban-rural and regional development. As an important national infrastructure, national economic artery, and mass transportation, railways shoulder major responsibilities in coordinating urban-rural and regional development. Speeding up the construction of high-speed railways is an inevitable requirement. In order to improve the competitiveness of the company, a motor car manufacturer hopes to conduct a detailed analysis of the front-end features of the motor car, such as hole positions, contours, and curvatures, and then improve the processing to enhance the competitiveness of the company.

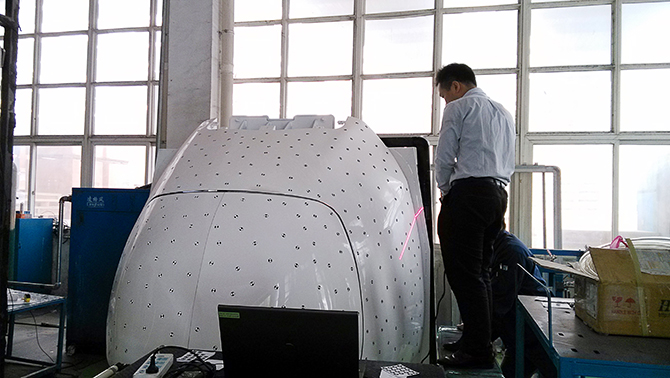

Scanned physical map of the front of the motor car

1. The customer scans the front end of the train in the factory workshop, so there is a higher requirement for the portability and stability of the 3D scanning equipment.

2. The customer's original data collection method is manual measurement, which has low accuracy and slow speed.

3. The quality of the front end of the EMU directly affects the overall performance of the EMU, and high accuracy is required for the acquired three-dimensional data of the front end of the EMU.

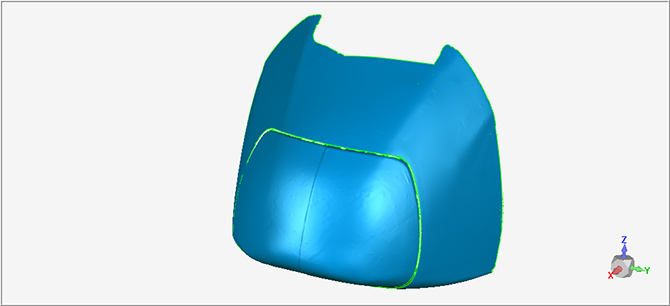

STL data map of motor car front

solution:

In response to the problems faced by customers, Huaguang engineers proposed to use in the solution: HL-3DH-3M (acquiring three-dimensional data of the front end of the train) + reverse design software Geomagic Studio (converting the point cloud data of the front end of the train into triangle mesh surface data) + Post-processing is carried out in mainstream design software such as Pro/E and UG to speed up the secondary design of the front end of the automobile. HL-3DH-3M is a handheld 3D scanner using laser as light source. It is easy to operate and easy to carry. The power interface is connected to a 12V/1A DC power supply, which is very suitable for small scanning environments or carrying on business trips.

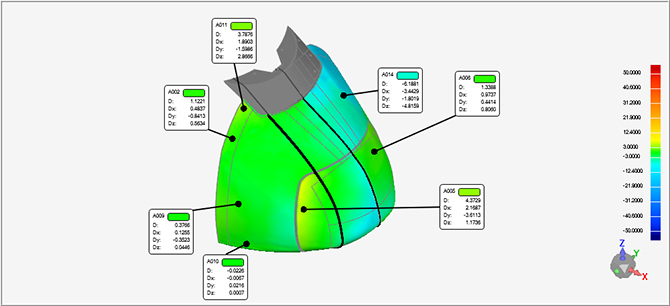

Comparison and analysis data map of EMU