Holon3d-3dp three-dimensional photogrammetry system is a handheld high-resolution digital camera, which takes digital photos of the measured object, and obtains the 3D coordinates of the measured object by the superposition of 2D digital photo images. This mobile technology can effectively save measurement time in capturing the 3D coordinates of the measured object, quality control and variant analysis. Hualang 3d-3dp industrial 3D photogrammetric system is the best of its kind with high precision. The 3DP photogrammetric system independently developed by Hualang 3D can reach the international level of similar products, and is an essential tool for 3D measurement of large workpieces.

Holon3d-3DP uses a high-resolution camera to calculate the three-dimensional coordinate values of key information points on the surface of the object by shooting multiple images of the object before and after the deformation, and obtain the object deformation data. It is developed on the basis of industrial digital three-dimensional photogrammetry research. Deformation measurement technology. Can be widely used: mechanical load test, thermal load test, environmental test, wind tunnel illumination simulation. Used for three-dimensional measurement of large size and large deformation, the measurement size range: 30mm~100m. It can measure the three-dimensional coordinates of the coding point and the mark point on the surface of large objects (several meters to tens of meters), and can be used with a three-dimensional optical surface scanning system , Quickly obtain high-precision three-dimensional data of super large objects, correct the point cloud information of large-area curved surfaces, and greatly improve the overall point cloud splicing accuracy of the three-dimensional scanner. It can compare the three-dimensional geometric shape of the tested workpiece with the CAD model, and quickly and conveniently detect the product shape quality of the large workpiece.

Application case: solar mirror measurement

Facing problems:

A domestic large-scale new energy company, because the trough solar reflector is more than 5m long and about 2.5m wide, the three-dimensional scanner equipment cannot complete the deviation of the solar reflector and the mounting hole of the bracket, and the deviation and deformation of the mounting hole between the bracket, It is very difficult for the company’s technicians to install solar mirrors, and the detection of solar mirror installation holes and brackets uses traditional detection methods. The detection speed is slow and time-consuming, which cannot meet the measurement needs of the company.

Solar Mirror Field Picture

solution:

According to the problems faced by the company, Holon3d technical engineers used the Hualang three-dimensional photogrammetric system to detect and analyze the installation holes and brackets of the solar mirrors, and provided effective solutions for the company's later installation and debugging of solar mirrors, and successfully solved them. Problems faced by customers.

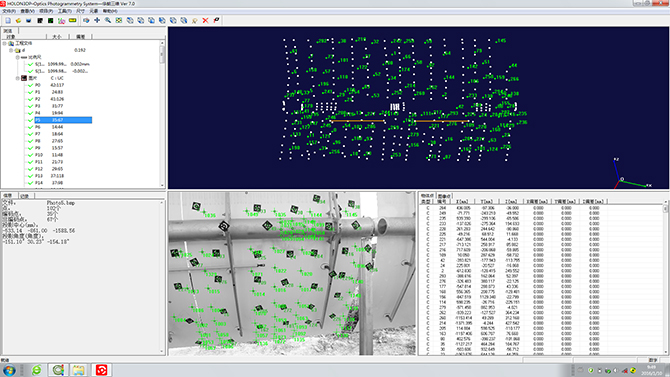

Solar mirror scanning scene

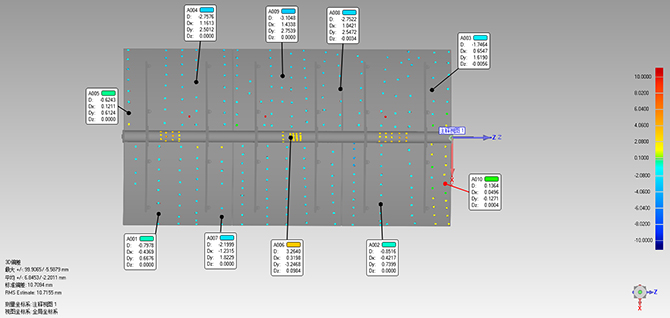

Three-dimensional inspection diagram of solar mirror

Three-dimensional photogrammetric data of solar mirror