The 3D printer is a cumulative manufacturing technique that uses a digital model file to create a three-dimensional object by printing a layer of bonding material. In order to better adapt to the needs of the market, the customer uses advanced 3D scanning technology instead of the traditional measuring method to detect the printer. It is hoped to obtain accurate 3D data, which can be used in later production improvement to improve all aspects of the printer and make it easier to use. Convenient and enhance competitiveness.

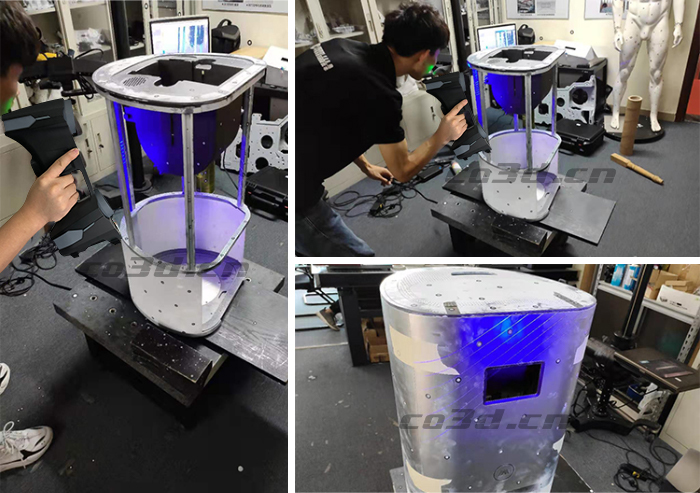

Printer real shot

Practical problems

The 3d printer is bulky and difficult to move during the scanning process. The overall shape has a curved shape, and the lower part has a transparent blank. The scanning laser easily penetrates the past, which brings certain difficulty to the scanning work.

For scanning workpieces, customers need to obtain high-precision data in a short period of time. Traditional 3D scanners take too long to scan, and transparent scanning is a difficult point and cannot achieve the desired effect.

Printer scan site map

Holon solutions

There is no way to solve the problem in the traditional measurement method, and it is impossible to obtain accurate data. Our engineers use the handheld 3D scanner Holon760. The first is to spray the developer in a transparent blank, and attach the marker points to position and splicing. Then use the 3D scanner to scan the high-precision 3D data of the 3D printer in a comprehensive and fast way. The scanning speed is fast and the time is very short. Flexible operation.

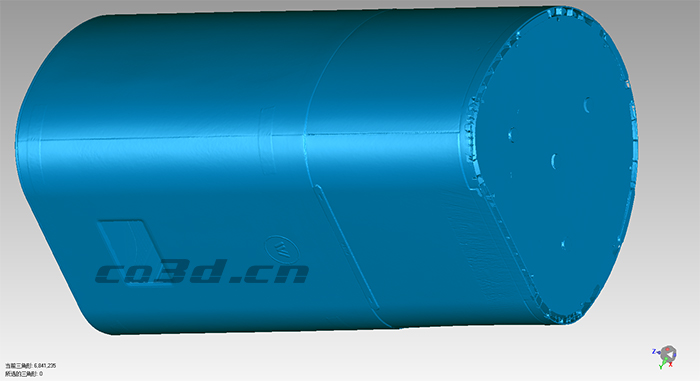

Printer STL data chart

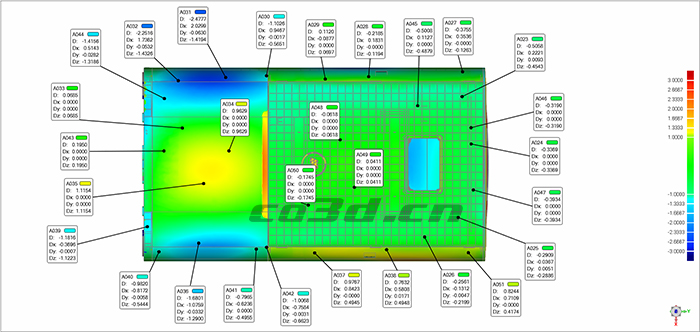

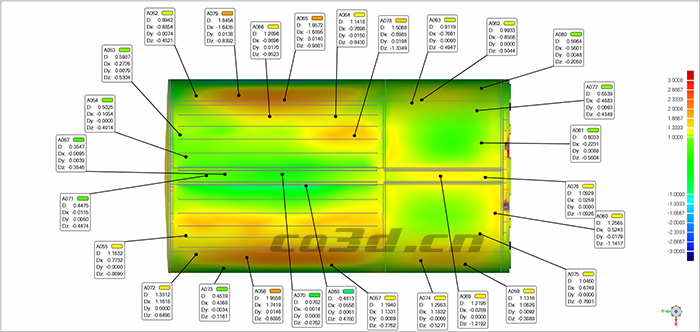

Then, the scanned three-dimensional data is imported into the three-dimensional detection software for processing, and compared with the original digital model of the printer to detect various aspects of the printer data. The handheld 3D scanner HOLON760 can quickly and accurately acquire the 3D scan data of each part under test, and the speed is fast, and the accuracy of obtaining data is high. The customer is very satisfied with the overall scanning process and the data. Successfully solved customer problems and provided accurate data as post-design support.

Printer STL data chart

Printer 3D data map

Printer 3D data map