A state-owned enterprise in Zhangjiakou needed to repair the shell of large coal mining machine components. Because there was no drawing, the repair work was difficult to carry out. The customer came to seek a solution and used our wireless handheld 3D scanner DRAKE to scan the coal mining machine to obtain high precision. The three-dimensional data was reversely repaired to reduce the company's losses. The final result was very satisfied with the customer and purchased our equipment.

Practical problems

The shell of coal mining machine parts is large and bulky, with different surface contours and many dead angles in the holes. Customers need to reverse repair the shell of coal mining machine parts. High data accuracy is required to achieve a perfect repair effect. Traditional measurement methods are inefficient and inefficient. The accuracy is not high, and it is difficult to accurately and quickly measure the overall structure of the coal mining machine component shell, which makes the later reverse design and modeling repair more difficult, and wastes too much manpower and material resources.

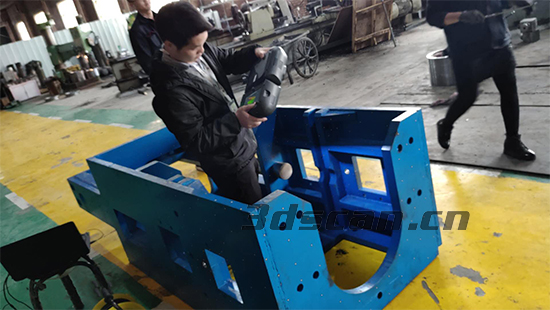

Holon engineer customer on-site scanning explanation

Holon solutions

Due to the complex structure, large volume and bulkiness of the shell of coal mining machine components, Hualang 3D technical engineers put forward a solution: use wireless handheld 3D scanner DRAKE to quickly obtain 3D data of the shell of coal mining machine parts, which is not only fast, convenient, and easy to operate. It takes short time and high data accuracy to meet the scanning needs of customers and successfully solve the problems faced by customers.

Three-dimensional scanning site map of coal mine machine parts

Scanning device:

Wireless handheld 3D scanner DRAK

Applicable fields:

Automobile scanning and parts, aircraft parts, boats, large blades, large castings, molds, impellers, engineering machinery, 3D printing, scientific research and teaching, etc.

Features:

1. Small size, light weight (2.3kg), easy to carry and use;

2. It can be used out of the box, no need to connect the data cable and power cable, and truly realize wireless 3D scanning;

3. Built-in computer and large-capacity battery (can work for 1.5 hours without interruption), real-time synchronous display on the touch screen;

4. Diversified scanning methods, dual-mode scanning with and without dots, for fast, efficient and reliable three-dimensional data collection;

5. The three modes can be switched flexibly, from small coins to large airplanes and yachts, which can easily complete the work. It is fast (only 15 minutes for car scanning), high efficiency, good effects, and no blind spots;

Three-dimensional scanning site map of coal mine machine parts

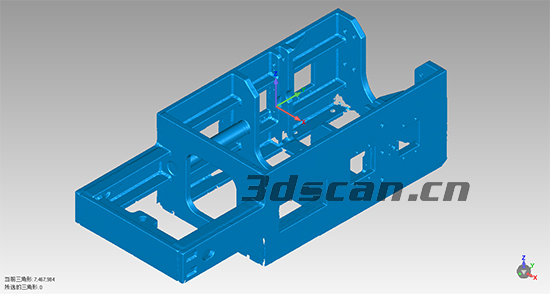

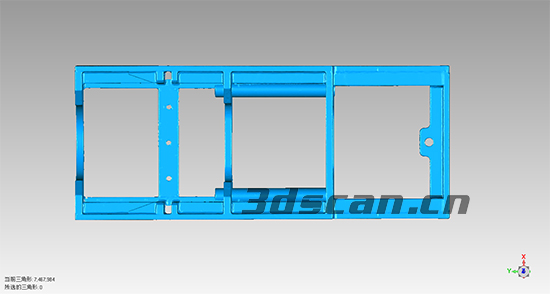

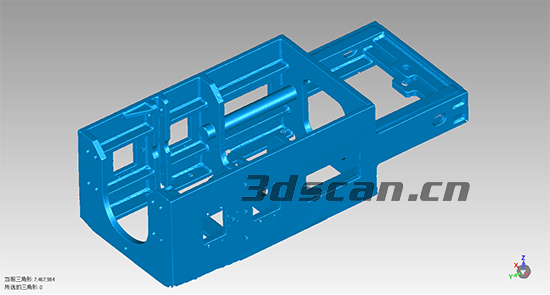

STL data diagram of coal mine machine parts

STL data diagram of coal mine machine parts

STL data diagram of coal mine machine parts